Establishing Operational Fatigue Limits for Short-Term Riser Operations

EVENT: OMAE

1 Jun 2015

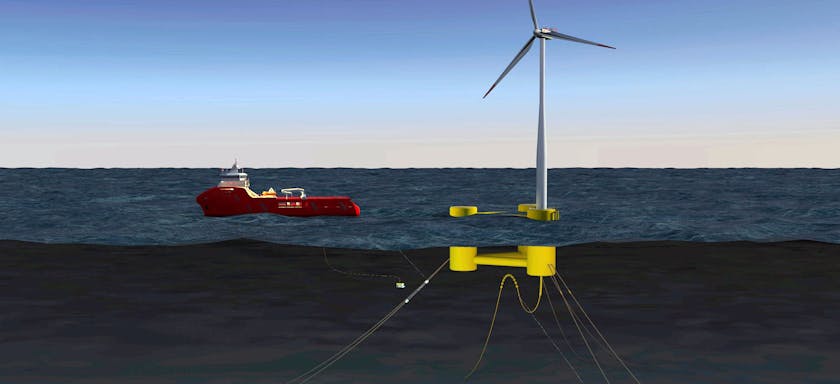

Drilling and intervention risers are widely used for oil and gas production in deep as well as shallow waters in oil fields around the world for subsea operations. The risers come in a diverse array of configurations, some of which may be challenged by fatigue if operated in high currents or seastates. The suitability of the selected riser and the operating limits are assessed by conducting strength and fatigue analysis based on design codes such as API RP 2RD, [7], API RP 16Q, [9], and API RP 17G, [10].

Typically, drilling and intervention activities are conducted for short periods of time but used repetitively. The codes are clear about the return period of the design environmental event which must be checked to insure safe operation with respect to strength; however, assessment of fatigue integrity can be more difficult to determine. The allowable fatigue operating environment should account for the ability to disengage, the time required to disengage, the damage rates in particular seastates, prior accumulation of fatigue damage, and variations in soil, tension and internal fluid weights.

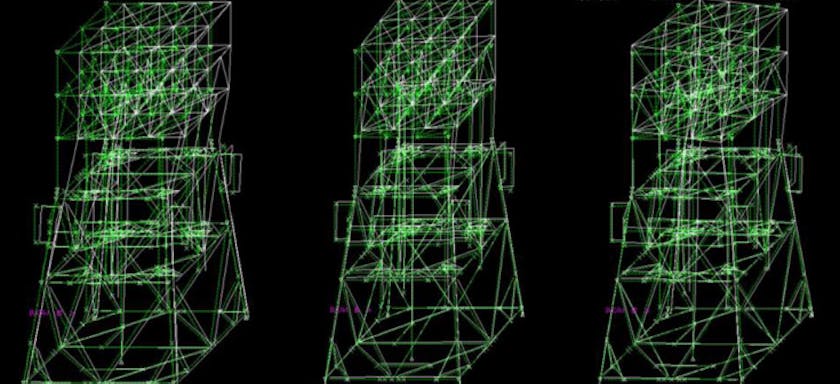

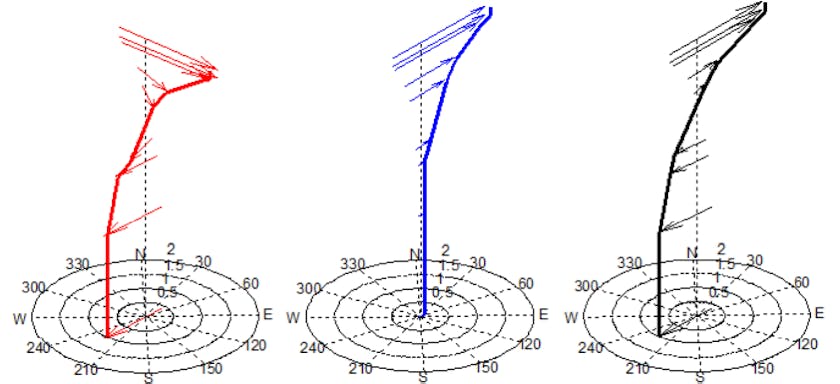

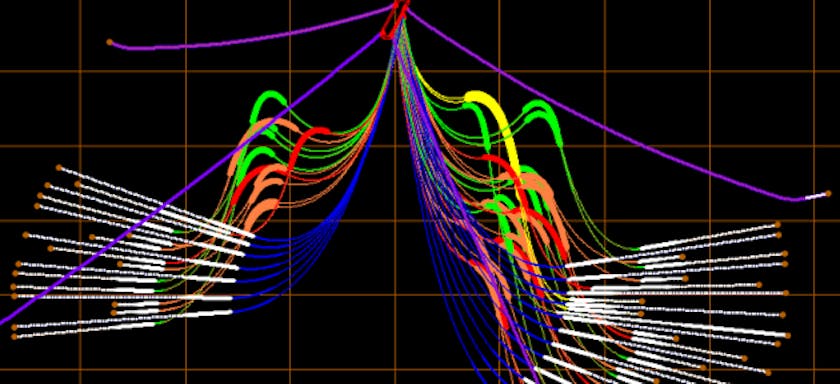

In this paper, an orderly method of establishing the allowable fatigue operation limits for drilling and intervention risers is presented based on Monte Carlo simulations along with a case study implementing the methodology in a shallow water environment. To illustrate this concept, a riser with wellhead and conductor system is assessed and is subjected to directional loading from several long-term seastates. The variation in effects is studied by doing fatigue analysis for different durations: 3 days, 1 week, 3 months, 1 year and 10,000 hours.

Authors

Phil Ward

Principal Engineer

About

Phil is a principal engineer in 2H’s Houston office. He holds a master’s degree in Engineering from Cambridge University and has 14 years’ experience in the oil and gas industry with various types of pipeline and riser designs, subsea structural monitoring systems, and late-life assessment techniques. Phil started his career with 2H in Aberdeen, and held the director position there before relocating to 2H Houston in 2019 with the goal of cross-populating experience with shallow and deep water systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigations, platform well design optimisation and thick-wall SCRs. Phil is a Chartered Engineer and Member of the Institute of Mechanical Engineers.

Expertise

Shankar Sundararaman

Senior Principal Engineer

About

Shankar Sundararaman is a Senior Principal Engineer with 2H Offshore. He has over 15 years' experience in the oil and gas industry, including design and numerical analysis of riser systems (drilling and completion risers, TTRs, SCRs, flexible risers), tendons, jumpers (rigid and flexible), machine learning (including digital twins) and cloud computing, structural health monitoring, drill string systems, drilling engineering analysis, and vibration analysis. He also has over 20 years engineering and R&D experience with numerical analysis, scientific computing, and finite element analysis. He has 5 granted patents, over 25 publications in international journals, conferences, and book articles, and presented at several international conferences. He has an undergraduate degree in Naval Architecture from IIT Madras, masters and doctoral degrees in Mechanical Engineering from Purdue University and is a Licensed Professional Engineer (Naval Architecture) in the State of Texas.

Insights

Luiza Ferreira

Principal Engineer

About

Luiza Ferreira has twelve years’ offshore engineering experience and currently is the Principal Engineer for renewable energy engineering activities for 2H Offshore’s California offices. She spent four years leading renewables engineering for 2H’s UK offices. She specialises in system engineering for floating and bottom-fixed offshore wind foundations and wave energy converters, and also has expertise in numerical analysis, structural design and engineering of subsea riser and conductor systems, including hybrid risers, rigid risers, drilling and completion risers, and flexible risers.