Integrity, Life Extension & Monitoring

Monitoring System Engineering

Our in-depth understanding of marine structural response and data analytics is what enables us to develop robust, project appropriate integrated monitoring systems to help clients accurately monitor and proactively manage the integrity of their offshore assets.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Bulent Mercan

Technical Advisor - Integrity Monitoring

About

Bulent is a technical advisor based in 2H’s Houston office where he is responsible for the development, management, and growth of integrity monitoring programs for subsea structural systems in the oil, gas and renewable sectors. Bulent has held numerous project management and technical leadership roles on a variety of projects like Measurement-based Wellhead Fatigue JIP, integrity monitoring (including drilling risers, wellheads, SCRs, TTRs, subsea jumpers), the structural and thermal assessment of power cables, and the analysis of seawater intake risers as part of decarbonization strategies. Bulent is a registered Professional Engineer in Texas and holds a Ph.D. in structural engineering from the University of Minnesota.

Insights

2H’s structural monitoring and data analysis experts recognise all the critical aspects involved in structural monitoring systems. We maintain a practical view and have a sound understanding of monitoring equipment options, installation drivers, and the operational needs of the client.

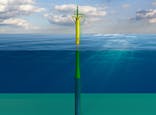

We provide structural monitoring services for a variety of offshore oil, gas and renewable assets. This includes wellhead and conductor systems, production and drilling risers, subsea jumpers, flowlines, umbilicals, and fixed and floating wind turbines. We have developed more than 500 structural monitoring programs for our clients all over the world.

Not only have our field data analysis results been used by clients to verify the structural integrity of their assets during extreme environmental conditions, but they have also helped us calibrate the analysis tools and to improve design assumptions for future developments. This has led to considerable cost benefits for our clients.

Monitoring System Specification

Developing an effective monitoring program requires an in depth understanding of structural system response to know how best to capture the data. Depending on our client’s monitoring objectives and budget, we recommend one of three data communication methods, i.e., standalone, hardwired, or acoustic. Next, we carefully specify the appropriate number of sensors, their locations, accuracy and sensitivity, equipment attachment method, and installation procedure.

Procurement & Installation

We will help identify the most appropriate monitoring system supplier and equipment based on our client’s monitoring requirements. In many cases, the monitoring equipment is available off-the-shelf and field proven. However, for unique monitoring objectives, we can witness and evaluate qualification testing of customised equipment. We also have experienced personnel who can oversee offshore installation.

Data Analysis & Management

We verify and analyse data quickly and reliably thanks to a suite of automated in-house tools which provide sensor data quality checks and data screening results in time and frequency domain. State-of-the-art, proprietary algorithms are used to calculate the fatigue accumulations of the offshore structures for the monitoring period.

Key Services

Monitoring System Specification

Response evaluation and instrument specification

Power and communication requirements

Attachment device design and installation procedures

Procurement & Installation

Supplier identification and qualification

RFQ preparation and bid evaluation

Procurement management and expediting

Witnessing and evaluation of qualification testing

Offshore installation/retrieval support

Data Analysis & Management

Data verification and screening

Detailed data analysis and model calibration

Extreme load and fatigue damage calculation

On-line data processing and KPI checking

Project Experience

BP – GoM Drilling Riser and Wellhead Monitoring Program

BP – GoM Intervention Riser (IRS) Monitoring Projects

Chevron – Anchor HPHT Wellhead Monitoring Program

Chevron – Tahiti SCR On-line Strain and Motion Monitoring

ENI – Devils Tower TTR Monitoring

Murphy – Kikeh GAP fluid transfer line monitoring

Noble – Rigid Subsea Jumper Monitoring

Offshore Brazil – Flexible riser armor wire failure monitoring system

Oxy – Constitution and Nansen TTR Monitoring

Shell – Mars, Bonga, and Gumusut SCR Monitoring Projects

Shell – BC10 FPSO mooring line monitoring

Total – Edradour Wellhead Monitoring

Woodside – NWS BOP motion monitoring

Key Personnel

Bulent Mercan

Technical Advisor - Integrity Monitoring

About

Bulent is a technical advisor based in 2H’s Houston office where he is responsible for the development, management, and growth of integrity monitoring programs for subsea structural systems in the oil, gas and renewable sectors. Bulent has held numerous project management and technical leadership roles on a variety of projects like Measurement-based Wellhead Fatigue JIP, integrity monitoring (including drilling risers, wellheads, SCRs, TTRs, subsea jumpers), the structural and thermal assessment of power cables, and the analysis of seawater intake risers as part of decarbonization strategies. Bulent is a registered Professional Engineer in Texas and holds a Ph.D. in structural engineering from the University of Minnesota.