Fixed Wind Foundations: An Independent Concept Screening Approach

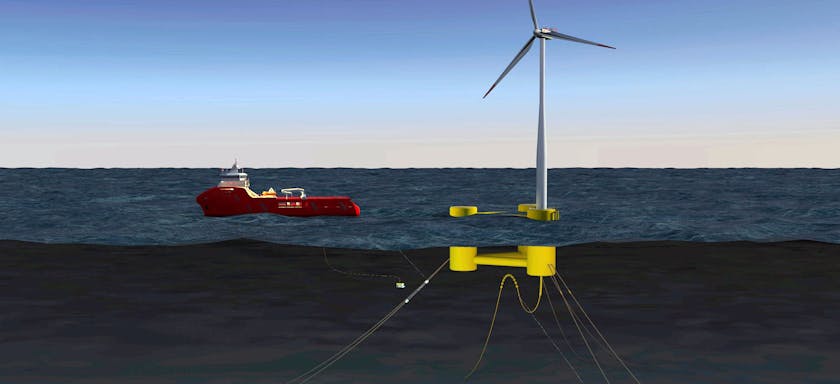

Although the renewable energy market is seeing rapid development of floating offshore wind, fixed wind technology is still the primary choice for offshore wind farms.

15 Apr 2021

Author

Luiza Ferreira

Principal Engineer

About

Luiza Ferreira has twelve years’ offshore engineering experience and currently is the Principal Engineer for renewable energy engineering activities for 2H Offshore’s California offices. She spent four years leading renewables engineering for 2H’s UK offices. She specialises in system engineering for floating and bottom-fixed offshore wind foundations and wave energy converters, and also has expertise in numerical analysis, structural design and engineering of subsea riser and conductor systems, including hybrid risers, rigid risers, drilling and completion risers, and flexible risers.

Language

In fixed wind, approximately 80% of the foundations installed worldwide today are monopiles. They offer several key advantages over other foundation types, such as simple design, serial fabrication and well-established transportation and installation procedures. However, in coming years, as wind farms expand into deeper waters (> 40m) with heavier turbines (10MW and beyond), foundations will also have to increase in size to offset the resulting increases in overturning moment. The overturning moment for a 15MW turbine, for example, more than doubles in comparison to a 10MW turbine; and the overturning moment of a 10MW turbine increases by 35% in 60m water depth compared to 20m.

Global expansion of fixed-bottom wind into new regions also brings a wider range of geotechnical conditions that need to be accommodated within the design and installation scheme while considering varying regulatory constraints.

This all introduces new challenges surrounding fabrication, materials, transportation, installation, supply chain and environmental impact. As a result, foundation selection is becoming increasingly development specific. But how exactly do you select the right foundation type? This article will explain a method to help weigh up all the relevant factors in order to make the best choice.

A Concept Screening Approach for Fixed Wind Foundation Feasibility

Selecting a wind turbine foundation is an extremely complex decision that must take many factors into consideration, from fabrication, installation, operation and environmental impact, to the levelized cost of energy (LCOE) over the life of the field (i.e. integrity management, life extension and decommissioning).

Assessing and comparing each of the bottom-fixed foundation types during the early planning phase of an offshore wind development will result in the most appropriate and cost-effective foundation selection and ultimately a more successful offshore wind project.

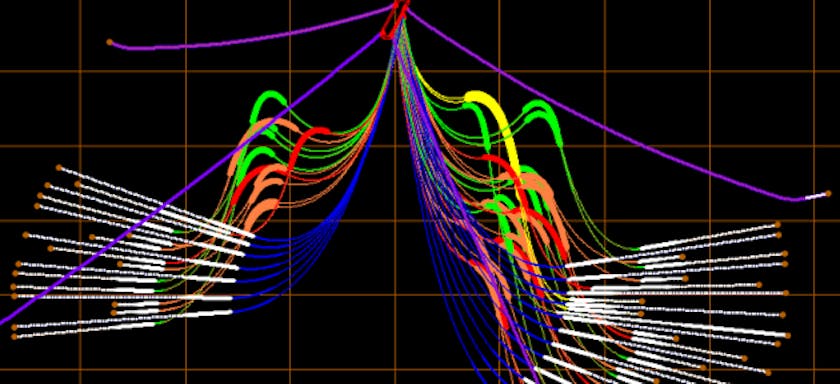

The main configurations of bottom fixed foundations that we typically assess in our concept-screening approach are:

Monopile

Suction bucket

Tripod

Jacket

Gravity base

Illustration-fixed-wind-foundation-types

Our assessment uses a risk-based scoring matrix aiming for independence and transparency to ensure that the most appropriate solution is reached. It considers the following parameters at a minimum, but can be customised to specific requirements:

Design

Manufacturability

Transportation

Installation

Environmental impact

Operation and IMMR (inspection, monitoring, maintenance and repair)

Decommissioning

The above parameters are also expanded into subcategories, for example, “duration” and “cost”. Each parameter is evaluated separately and pertinent details are noted.

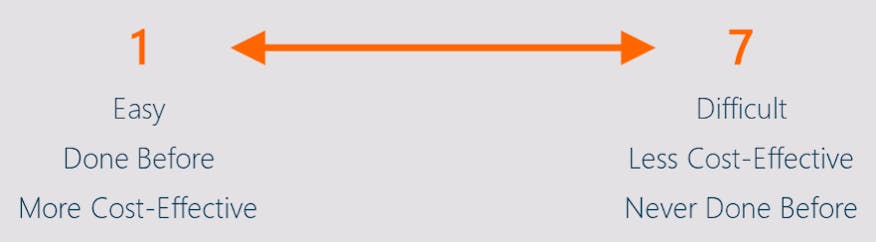

The rating system for each sub-parameter is scaled from 1 to 7. Lower scores mean that the foundation is more cost-effective and/or has a higher technology readiness level (TRL). Higher scores represent structures that are less cost-effective and/or have a lower TRL and consequently represent higher risk.

Parameter scoring system

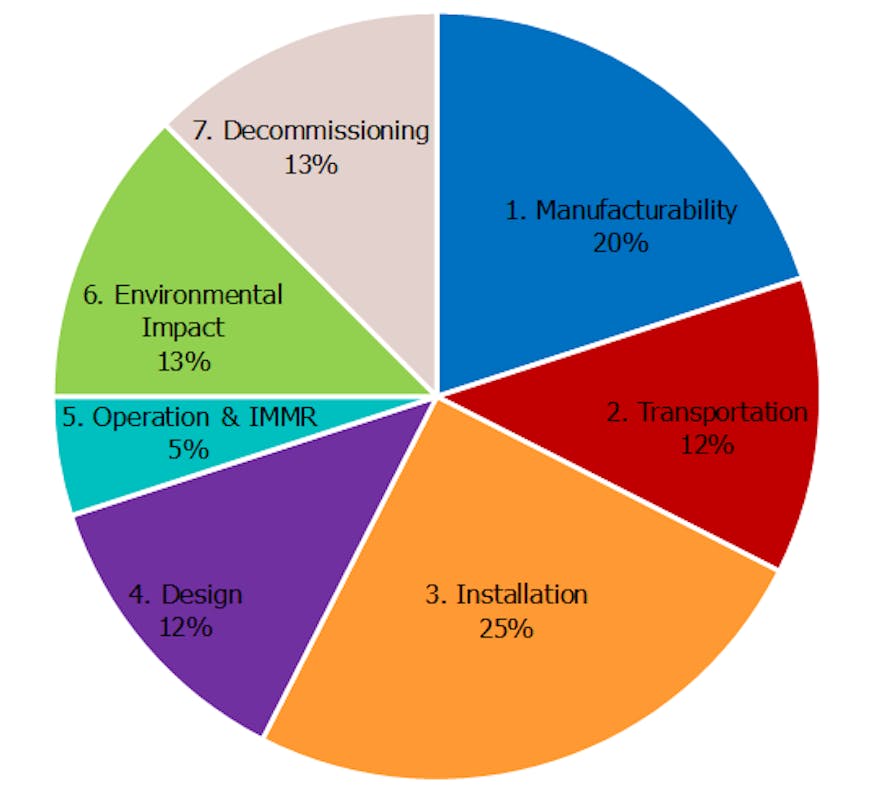

Parameters are also given a weighting factor to represent their importance of the overall scoring. The weighting factor can be highly impacted by regional constraints since wind markets, supply chains and regulations can vary significantly from region to region. To define the weighting factor, we assess the following for the region in question:

Regional regulatory requirements

Project scale – number of wind turbine generators (WTG), WTG size and array

Geotechnical and metocean conditions

Local supply chain

Other factors that can impact the weighting factor are variations of water depth and geotechnical characteristics across the wind farm site which, if not available, can lead to uncertainties.

The pie chart below shows an example of weighting factor applied to different parameters in a site-specific assessment. In this scenario, the highest weight is assigned to “installation”, followed by “manufacturability”. A high weighting factor in “installation” can be due to uncertainty of the geotechnical data, leading to the unpredictability of the installation equipment. On the other hand, the installation weighting factor may be lowered if a comprehensive site survey has been carried out at the wind farm site and the data is readily available for the screening process. Alternatively, if a wind farm has high environmental restrictions, the weighting factor for “environmental impact” would be higher than the 13% shown in the chart.

Site-Specific Weighting Factor Example

The Screening Process

With the foundation types, parameters and weighting factors defined, a scoring matrix is completed in 2 steps:

In step one, rates from 1 to 7 are assigned to each foundation type against each parameter and/ or sub-parameter to show how a foundation type compares to the others. For example:

For a wind farm with strict regulatory requirements for decommissioning, concepts with suction buckets may score lower since they can be removed by reverse pumping.

Installation scores will depend heavily on the geotechnical conditions – specifically the TRL of drilling, driving, and suction installation methods. A good understanding of the technology limits is critical to an accurate assessment of this.

Manufacture and transportation scores will depend on the maturity of the local supply chain and vessel market. Local knowledge is an advantage here.

A foundation type that needs extensive seabed preparation due to geotechnical conditions (e.g. dredging and disposal of materials) would receive a higher score than one that does not.

In step two, the weighting factor is applied to the average rate from all sub-parameters of the same parameter. This will summarise the results, accounting for the rates and weighting factors, and will indicate the foundations that offer the best solution for the specific site under assessment.

The screening results could also indicate that more than one solution is recommended for the wind farm if factors such as soil properties and water depth vary across the site.

Summary

The screening process of fixed wind foundations is complex and the amount of research and expertise that goes into defining the weightings and determining the scores can be significant. To achieve an accurate and thorough assessment, it is critical to understand the full life cycle and to thoroughly analyse all seven parameters mentioned above. For maximum success, we believe having a balance of independence (i.e. being agnostic to vessels and concepts), and the necessary technical expertise is key. 2H Offshore is an independent, unbiased engineering contractor and we are fortunate to be able to access expertise from our sister companies in the Acteon Group who specialise in installation, geotechnical, IMR, transportation and decommissioning, and have an increasingly global footprint which allows us to bring local expertise in newer markets.

As the industry deploys larger turbines, in deeper water, across a wider range of geotechnical and regulatory domains, the need to select optimal foundations becomes increasingly important. Choosing the right foundation to minimize cost and risk to the offshore wind farm and the environment is critical to a successful development and to achieving a low LCOE.

2H Offshore offers independent, unbiased expertise to support wind developers and EPCI contractors in making the best choices for their offshore wind development.

To learn more about our Concept Screening for Fixed Wind Foundations, watch our on-demand webinar: Benefits of Independent, Installation-Led Concept Screening for Fixed Wind Turbine Foundations (link/CTA)

Author

Luiza Ferreira

Principal Engineer

About

Luiza Ferreira has twelve years’ offshore engineering experience and currently is the Principal Engineer for renewable energy engineering activities for 2H Offshore’s California offices. She spent four years leading renewables engineering for 2H’s UK offices. She specialises in system engineering for floating and bottom-fixed offshore wind foundations and wave energy converters, and also has expertise in numerical analysis, structural design and engineering of subsea riser and conductor systems, including hybrid risers, rigid risers, drilling and completion risers, and flexible risers.

Language

For more information on this topic, please get in touch.

Contact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.