Application of Casing Wear Theory to Top Tensioned Risers

EVENT: DOT

1 Oct 2015

During drilling and/or workover operations through a production top tensioned riser, the riser will experience contact with the rotating drill string, resulting in wall loss from the riser. This wall loss from the contact between the rotating drill string and riser is defined as riser wear.

Riser wear is primarily a function of riser curvature, which is dependent on riser stiffness, environmental loading, vessel offset, drilling operational parameters and drilling mud properties. Wear allowance and windows for conducting drilling operations can be defined prior to wear analysis. This paper discusses a complete methodology to determine riser wear, through application of casing wear theory, and thus confirm the wear allowance for the given drilling operating windows.

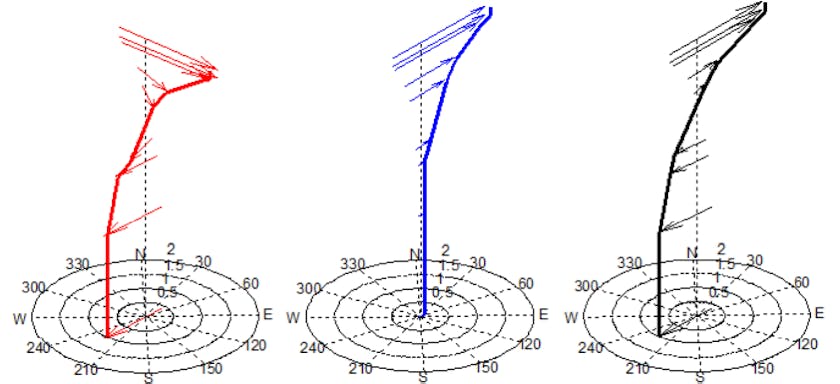

Environmental loading conditions are selected based on drilling windows and a global analysis is performed with FEA software to obtain riser curvatures. As casing wear theory and associated software are based on survey parameters, the riser curvatures obtained from FEA software are converted to survey parameters (i.e., total vertical depth (TVD), inclination, and azimuth) using the Minimum Curvature Method. Contact forces between the drill string and riser are determined based on torque and drag theory, and a cumulative wear volume is calculated considering drilling operational parameters. Various approaches for converting this cumulative wear volume to wall thickness loss are presented and compared.

Authors

Suneel Patel

Principal Engineer, USA

About

Suneel Patel is a Chartered Engineer (CEng IMarEST) with over 12 years of experience in the design, verification, fabrication and installation of drilling, production and export riser systems. He is experienced in the global finite element analysis of risers (top tension risers, steel catenary risers, steel lazy wave risers, flexible risers). Other experiences include global assessments of subsea pipelines, subsea umbilicals, the global finite element analysis and installation of tension leg platform (TLP) tendons, riser structural monitoring, riser integrity management and developing offshore procedures for riser installation. He has experience in pre-FEED, FEED and detailed design projects in the Gulf of Mexico, offshore Brazil and offshore Australia.

Adam Szucs

Senior Principal Engineer, USA

About

Adam has over 22 years of engineering experience with a variety of offshore riser systems ranging from conceptual design and feasibility to detailed design and installation. He has held several project management and technical leadership roles on a variety of projects, and specialises in top tensioned and freestanding hybrid risers. Adam graduated from Texas A&M University with a Bachelor’s degree in Maritime Systems Engineering.

Shankar Sundararaman

Senior Principal Engineer

About

Shankar Sundararaman is a Senior Principal Engineer with 2H Offshore. He has over 15 years' experience in the oil and gas industry, including design and numerical analysis of riser systems (drilling and completion risers, TTRs, SCRs, flexible risers), tendons, jumpers (rigid and flexible), machine learning (including digital twins) and cloud computing, structural health monitoring, drill string systems, drilling engineering analysis, and vibration analysis. He also has over 20 years engineering and R&D experience with numerical analysis, scientific computing, and finite element analysis. He has 5 granted patents, over 25 publications in international journals, conferences, and book articles, and presented at several international conferences. He has an undergraduate degree in Naval Architecture from IIT Madras, masters and doctoral degrees in Mechanical Engineering from Purdue University and is a Licensed Professional Engineer (Naval Architecture) in the State of Texas.

Insights

David Saldaña

Senior Engineer, USA

David Saldaña

Senior Engineer, USA

Insights

Pete Padelopoulos

Senior Principal Engineer, USA

Pete Padelopoulos

Senior Principal Engineer, USA

Insights

Kamal Raghavan

Chevron Energy

Metin Karayaka

Chevron Energy