Fixed Wind

Pre-Piling Templates

2H custom-engineers pre-piling templates for the fixed offshore wind industry to ensure that jacket foundations are installed efficiently, reliably and cost-effectively.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Ben Andrew

Director, UK

About

Ben has over 17 years of specialist engineering experience in the design and analysis of offshore platforms, foundations, cables, and riser systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design based out of our London, Kuala Lumpur and Houston offices.

As one of the UK directors, Ben’s current focus is on the development of our minimum facilities platforms and fixed offshore wind offerings for the European, Middle East and Africa markets. Ben is a graduate of Oxford and Imperial Universities with a Bachelor’s degree in Mathematics, and a Master’s in Quantum Physics.

Insights

David Knights

Senior Project Manager, UK

About

David has over 19 years of industry experience covering a wide range of marine construction projects, both on and offshore. An experienced team leader, he has successfully delivered many projects across the offshore renewables, civil engineering and oil & gas sectors. He has extensive experience throughout project lifecycles and has been responsible for the delivery of various pioneering solutions within the offshore foundations industry.

Previous experience includes management of the design and delivery of numerous pre-piling template systems, resulting in the successful installation of nearly 1000 piles for multiple offshore renewable projects.

David has a First Class Masters Degree in Civil Engineering and is a Chartered Engineer.

Expertise

Owen Pocock

Principal Engineer, UK

About

Owen is a Principal (chartered) Engineer with over ten years’ specialist experience in advanced numerical analysis and structural engineering of offshore wind farms, drilling and production riser systems. Owen’s oil and gas project portfolio covers a range of riser types and systems (rigid and flexible) in deep and shallow water around the globe. He has also performed numerous engineering assessments and package management roles for both fixed-bottom and floating wind farm developments. Owen is experienced in concept, pre-FEED, FEED and Detailed Design for EPCI projects.

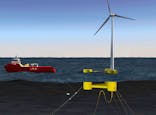

Jackets are a popular choice of fixed wind foundation in water depths of 30m-70m due to their maturity and use of smaller piles which are easier to install than monopiles. Jacket foundation piles are usually pre-installed for efficiency and installation is done using a pre-piling template to ensure that they are installed in the correct place and within the appropriate tolerances. As a result, pre-piling templates require a precise and intelligent design process to ensure they are fit for purpose.

Full EPCI capabilities

2H provides complete design and engineering services for pre-piling templates. Our global footprint and partnerships with local supply chains and fabrication yards around the world mean that we can also undertake the full engineering, procurement, construction and installation scope.

Design Considerations for Pre-Piling Templates

The installation of jacket piles is a precise operation and depends on the quality of the pre-installed piling operation. Pre-piling templates therefore generally need a number of secondary features:

A hydraulic levelling system to ensure that the template is orientated horizontally for accurate positioning of the piles.

Hydraulic pile guides to accurately position piles during installation process. These tend to be retractable to allow passage of the piling hammer.

Active controls functionality to aid the above.

Survey systems to ensure the templated is orientated and positioned correctly at the turbine location.

Project-specific features such as noise suppression to reduce the acoustic effects of the hammer and mudmat breakout mitigation systems to ensure that the structure can be retrieved in a variety of soil conditions.

Pre-piling template configurations can vary significantly as the design needs to suit the size of the jackets being installed, the number of piles associated with each jacket, and the installation method used by the vessel selected for the project. There are also options around whether the pre-piling template is standardised for specific applications, or whether the structure is designed to be adjustable for use on multiple projects with different specifications.

Pre-piling template configurations can vary significantly as the design needs to suit the size of the jackets being installed, the number of piles associated with each jacket, and the installation method used by the vessel selected for the project. There are also options around whether the pre-piling template is standardised for specific applications, or whether the structure is designed to be adjustable for use on multiple projects with different specifications.

2H understands there is a range of options that could be considered in terms of template size, shape, design and functionality and we work with our clients’ specific requirements to develop the most appropriate template design for the project.

Key Services

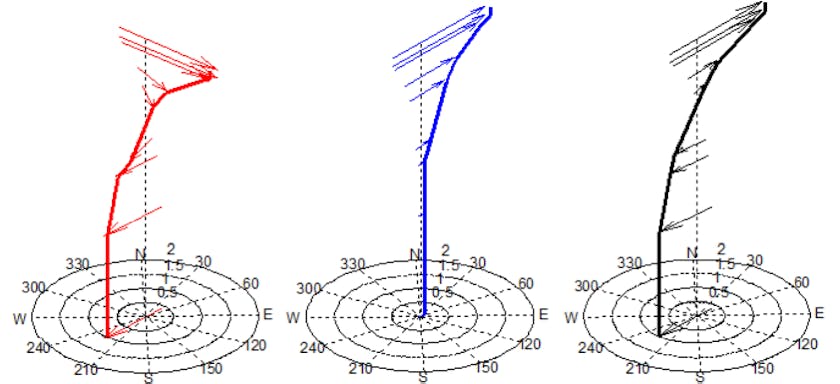

Structural modelling

In-place structural analysis and design

Geotechnical design (inc. mudmat sizing)

Controls and hydraulics systems design

Lifting and installation analysis

Project Experience

Offshore WindForce – Wikinger – design, supply of specialist equipment, commissioning and operation of a pre-piling template for 70 4-legged jackets and larger diameter OSS piles

DEME – Moray East – detailed design and engineering support for a pre-piling template for 103 3-legged jackets

HMC – Greater Changhua – detailed design of a pre-piling template for 111 3-legged jackets

Key Personnel

Ben Andrew

Director, UK

About

Ben has over 17 years of specialist engineering experience in the design and analysis of offshore platforms, foundations, cables, and riser systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design based out of our London, Kuala Lumpur and Houston offices.

As one of the UK directors, Ben’s current focus is on the development of our minimum facilities platforms and fixed offshore wind offerings for the European, Middle East and Africa markets. Ben is a graduate of Oxford and Imperial Universities with a Bachelor’s degree in Mathematics, and a Master’s in Quantum Physics.

Insights

David Knights

Senior Project Manager, UK

About

David has over 19 years of industry experience covering a wide range of marine construction projects, both on and offshore. An experienced team leader, he has successfully delivered many projects across the offshore renewables, civil engineering and oil & gas sectors. He has extensive experience throughout project lifecycles and has been responsible for the delivery of various pioneering solutions within the offshore foundations industry.

Previous experience includes management of the design and delivery of numerous pre-piling template systems, resulting in the successful installation of nearly 1000 piles for multiple offshore renewable projects.

David has a First Class Masters Degree in Civil Engineering and is a Chartered Engineer.

Expertise

Owen Pocock

Principal Engineer, UK

About

Owen is a Principal (chartered) Engineer with over ten years’ specialist experience in advanced numerical analysis and structural engineering of offshore wind farms, drilling and production riser systems. Owen’s oil and gas project portfolio covers a range of riser types and systems (rigid and flexible) in deep and shallow water around the globe. He has also performed numerous engineering assessments and package management roles for both fixed-bottom and floating wind farm developments. Owen is experienced in concept, pre-FEED, FEED and Detailed Design for EPCI projects.