Using Natural Frequency Response Monitoring (NFRM) to Reduce Inspection Costs for Ageing North Sea Platforms

EVENT: Offshore Europe

1 Sep 2017

The offshore industry is faced with a tough financial market, requiring innovative solutions in order to reduce costs and increase operational efficiency. This includes solutions to ensure that maintaining the structural integrity of North Sea platforms is achieved as cost-effectively as possible without increasing risk or compromising safety.

Regular general visual inspection of fixed platforms for structural damage, by ROV fly-by, is a commonly used technique. There are two main concerns with this technique. Firstly, these inspections are costly to perform and secondly, damage may occur shortly after a scheduled inspection and go undetected until the next inspection. Both of these concerns are addressed through real-time structural monitoring. This uses automation of frequency detection and signal processing in order to avoid equipment and personnel mobilisations and provide immediate notification of potential damage. Inspections can then be conducted only when required and targeted at a specific area of interest, resulting in a significant reduction in overall integrity management costs. A platform monitoring system can be used on both manned and unmanned platforms and can be installed during construction or retro-fitted to an older installation.

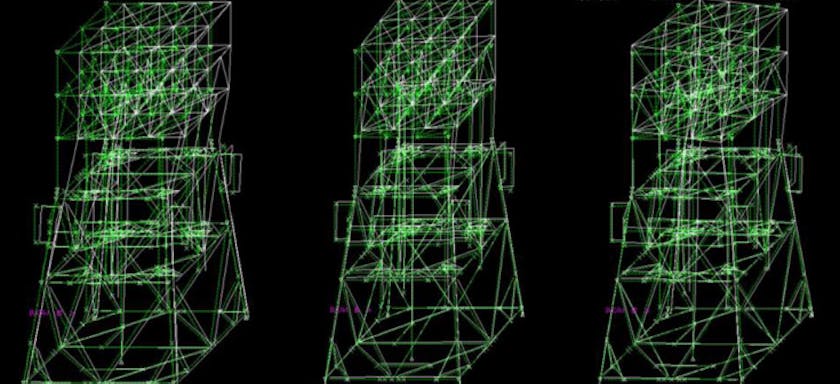

A platform monitoring system, also known as Natural Frequency Response Monitoring (NFRM), works by measuring the natural frequency response of the platform under wave loading. The structural failure of a member will alter the natural frequency of the platform and the monitoring system will detect the change and alert the Operator. Prior to implementing this technique a screening study of the change in platform response following damage to critical members is necessary in order to ensure that incidents will be reliably detected

This paper presents a case study of a NFRM screening study prior to installation of the system on a North Sea platform. The structural analysis used to confirm the suitability of the NFRM system and the method for specifying the monitoring system itself are described. An indicative cost of procuring and installing the NFRM system is also presented.

Authors

Phil Ward

Principal Engineer

About

Phil is a principal engineer in 2H’s Houston office. He holds a master’s degree in Engineering from Cambridge University and has 14 years’ experience in the oil and gas industry with various types of pipeline and riser designs, subsea structural monitoring systems, and late-life assessment techniques. Phil started his career with 2H in Aberdeen, and held the director position there before relocating to 2H Houston in 2019 with the goal of cross-populating experience with shallow and deep water systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigations, platform well design optimisation and thick-wall SCRs. Phil is a Chartered Engineer and Member of the Institute of Mechanical Engineers.

Expertise

Elaine Whiteley

Senior Engineer

About

Elaine is a senior engineer in 2H’s Houston office. She holds a master’s degree in Structural Engineering from Heriot Watt University and has 12 years’ experience in the energy industry. Elaine is a Chartered Engineer and Member of the Institute of Civil Engineers. Her experience focuses on a range of different riser designs, shallow water conductor systems and subsea structural analysis. Elaine started her career with 2H in Aberdeen before relocating to 2H Houston in 2019 to broaden her experience to different riser systems. She has held numerous project management and technical roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigation, shallow water platform conductor integrity management and seawater intake riser design.

B. Taylor

Pulse Structural Monitoring