Subsea Well Life Extension Fatigue Challenges

EVENT: SPE Bergen

1 Apr 2015

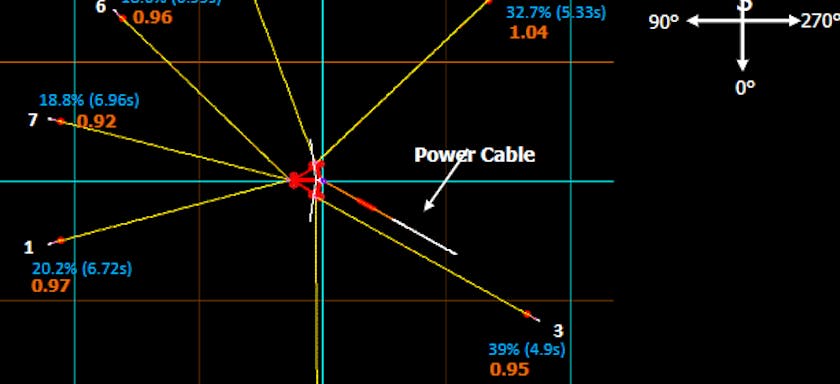

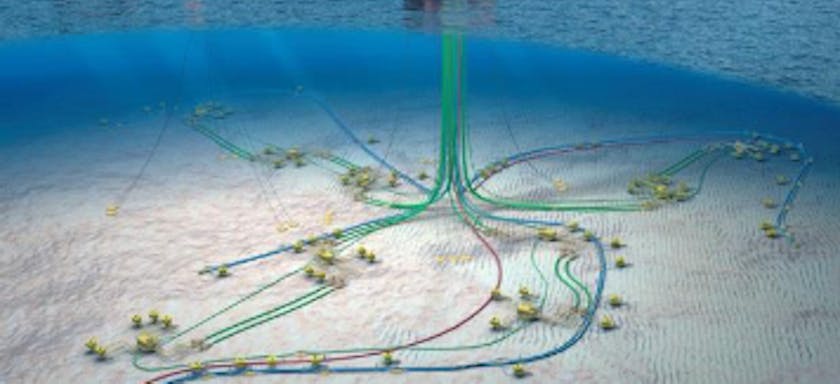

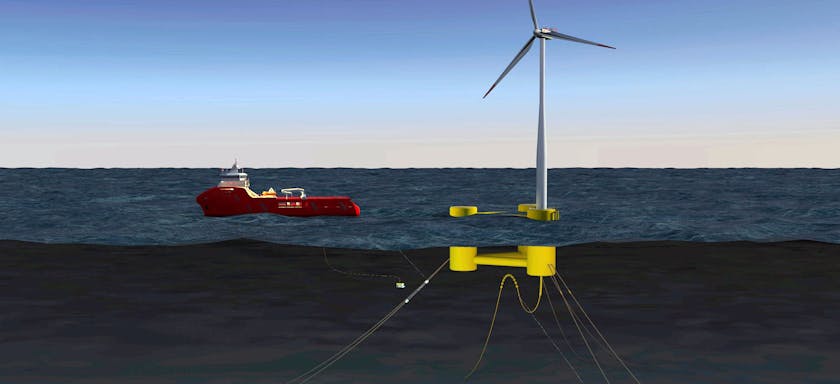

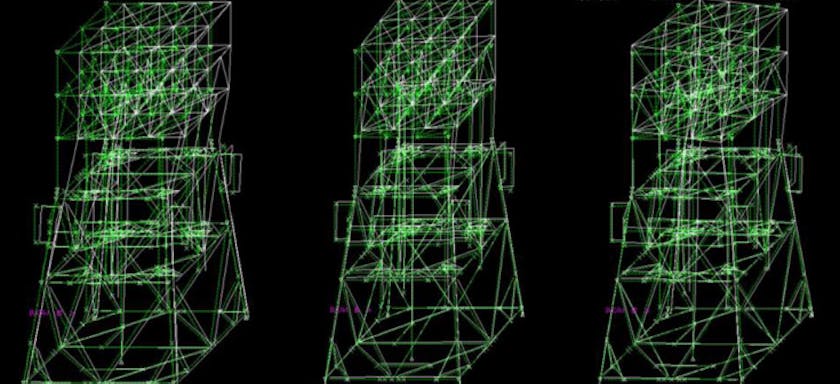

The growth in oil price and improvement in techniques for recovery of oil is resulting in an increasing need to keep subsea wells that have exceeded that initial design lives in operation. Life extension will require further drilling on the wells, the feasibility of which must be assessed in terms of the fatigue damage accumulation in the wellhead system. Consideration of fatigue resistance in the design of older wells was limited, if conducted at all, which has resulted in design features that form fatigue hotspots. Such features, coupled with the additional loading applied in further operations can lead to severe challenges in demonstrating fitness-for-purpose in terms of fatigue response.

Calculation of fatigue damage from both previous and future operations is conducted to demonstrate acceptable response. This analysis typically involves a number of assuptions that err on the side of conservatism. However, the severity of loading is such that steps must be taken to minimise these conservatisms where reasonably possible in order to meet faigue life targets. This in itself may not be enough, and the use of in-service monitoring and even component fatigue testing may be needed to meet the required objectives. This paper gives an overview of the design challenges that are faced in extending the service life of older wells, the steps that can be taken to improve calculated fatigue lives and how further steps such as in-service monitoring may be used to demonstrate fitness-for-pupose.

Authors

Alex Rimmer

Director, UK

About

Alex is a Chartered Engineer with a first-class master’s degree in mechanical engineering from the University of Bath and has been working for 2H Offshore since 2004. Alex has significant experience in the design and analysis of drilling and production systems for deepwater and shallow water developments, most notably as lead analysis engineer for BP’s Block 31 PSVM freestanding hybrid riser design project. Alex has taken on a number of managerial roles at 2H, including technical manager of the Norwich office, where he was responsible for integrating UWG’s shallow water riser and conductor engineering team and business into 2H. He has been a director in our London office since 2011.

Language

Insights

Phil Ward

Principal Engineer

About

Phil is a principal engineer in 2H’s Houston office. He holds a master’s degree in Engineering from Cambridge University and has 14 years’ experience in the oil and gas industry with various types of pipeline and riser designs, subsea structural monitoring systems, and late-life assessment techniques. Phil started his career with 2H in Aberdeen, and held the director position there before relocating to 2H Houston in 2019 with the goal of cross-populating experience with shallow and deep water systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigations, platform well design optimisation and thick-wall SCRs. Phil is a Chartered Engineer and Member of the Institute of Mechanical Engineers.