Enhancing Coil Tubing Offshore Operating Limit Case Study

EVENT: SPE ICoTA Well Intervention Conference

22 Mar 2023

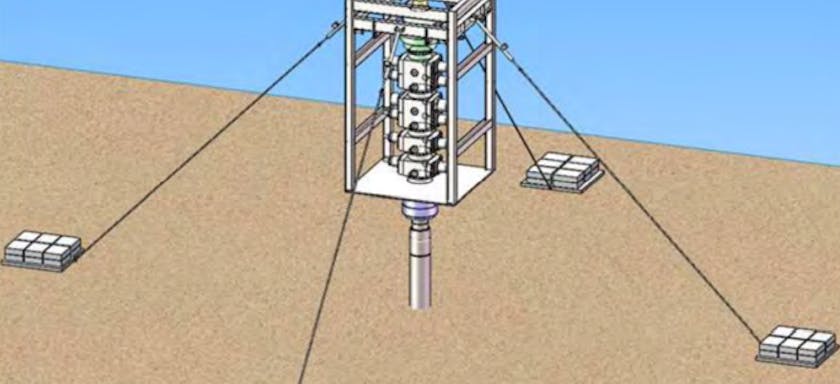

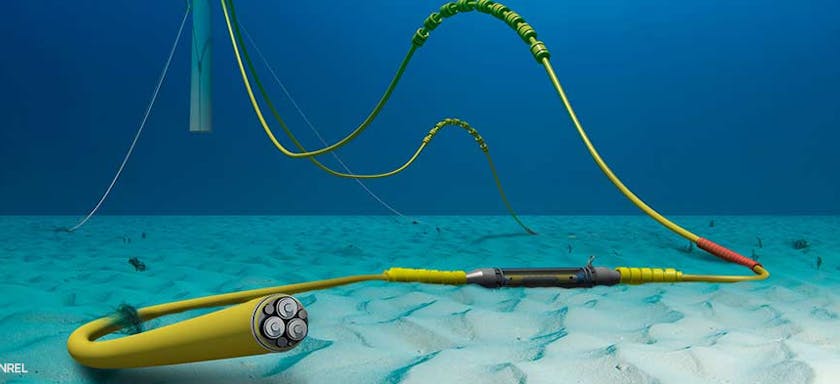

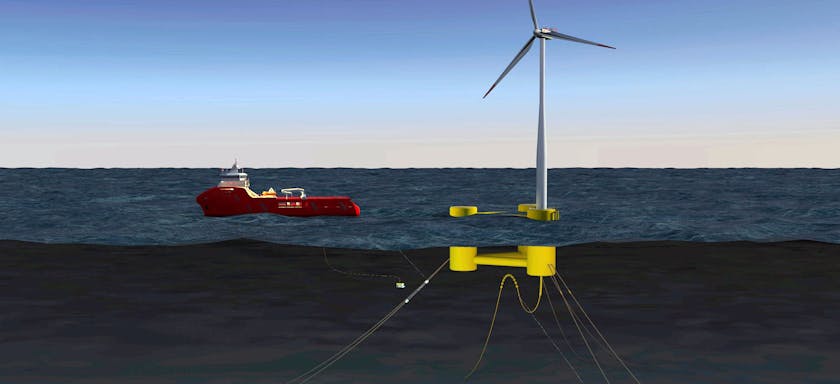

Coiled tubing (CT) is being increasingly used in open water mode for offshore light well intervention such as subsea hydraulic pumping applications. Traditionally coiled tubing has been popular in land based intervention applications; whereas for offshore applications using a CT deployed through a riser (in-riser mode) is very common.

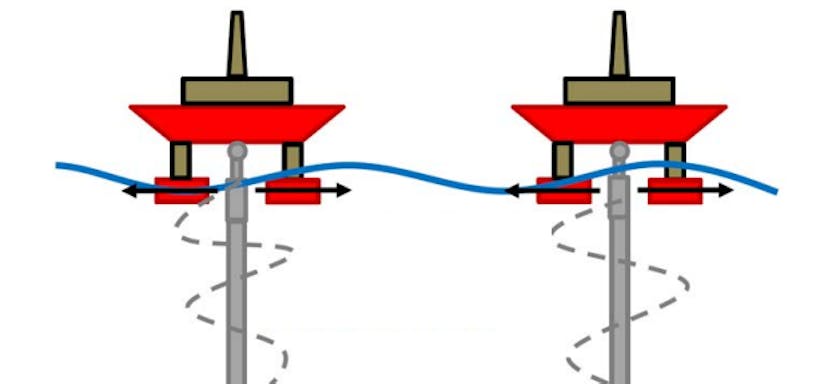

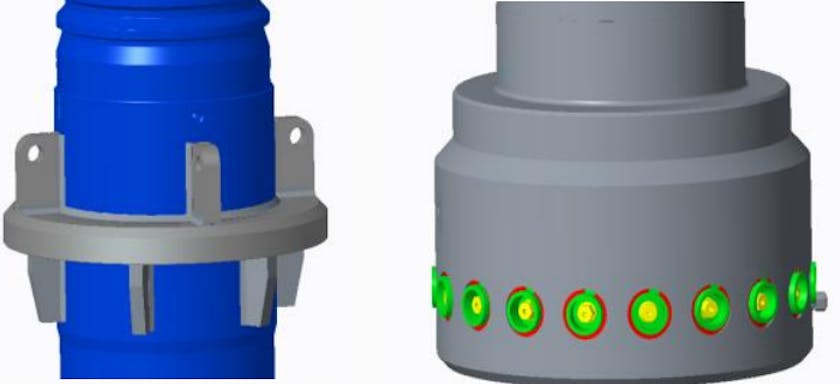

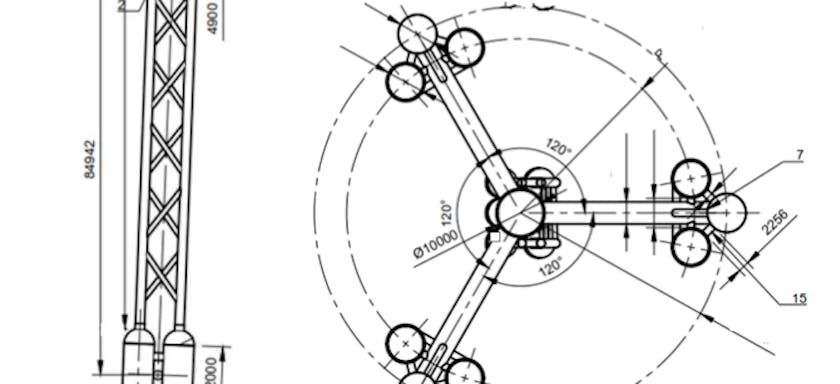

However more recently, light well intervention (LWI) operations with CT deployed in open water mode are gaining traction due to improved efficiencies compared to traditional intervention methods. Coiled tubing systems are an integral part of a LWI system and are used for injection and hydraulic pumping operations. In open water mode coiled tubing pipe is susceptible to direct hydrodynamic loading from waves and currents and vessel motions. The strength response and fatigue performance of the coiled tubing pipe can severely limit operability and increase down time for these operations when compared to riser based operations.

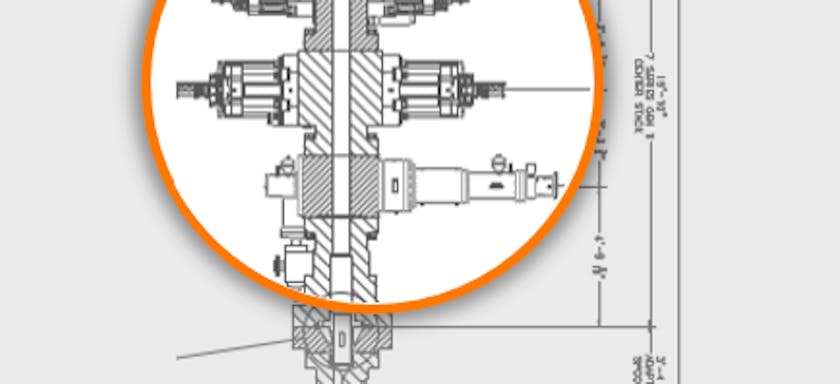

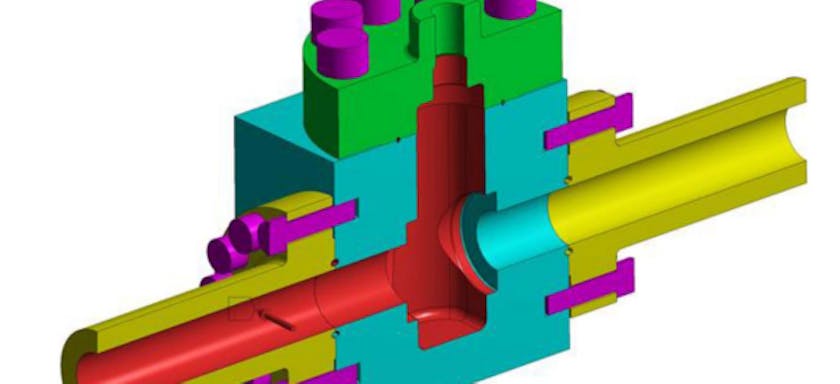

In this paper we will present a case study where coiled tubing has been used for LWI and subsea pumping operations. The paper will highlight some of the key challenges in design and operation of open water mode CT systems for offshore applications, from a loading standpoint and will also discuss challenges arising from lack of industry standards and codes. Analysis methodology and outcomes from this study will be presented to demonstrate how the CT strength response limits operations. Multiple mitigation options that were used to enhance operability will be discussed: these include judicious use of operational parameters, field measurement based environmental data and pipe depressurization to attain feasibility in harsh environments. In addition, modeling refinements based on 3 Dimensional (3D) Finite Element Analysis (FEA) of the CT injector guides and strain based design criteria will be discussed.

The paper will include recommendations based on experience from these case studies and highlight the need for a common industry standard to better assist Operators and OEMs with future designs.

Authors

Mahesh Sonawane

Technical Advisor - Drilling & Completions

About

Mahesh Sonawane is a Technical Advisor for Drilling and Completions with 2H Offshore in Houston. He has a Masters of Science in Mechanical Engineering from Texas A&M University, Mahesh had over 15 years experience in global riser analysis and specialized in drilling and completion risers, HPHT equipment and riserless well intervention systems for offshore applications.

Expertise

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Ben Toleman

Principal Engineer

Ben Toleman

Principal Engineer

Michael Long Ge

BP America