Vessel Interface Considerations for Ultra Deepwater Intervention Risers

EVENT: OMAE

1 Jun 2019

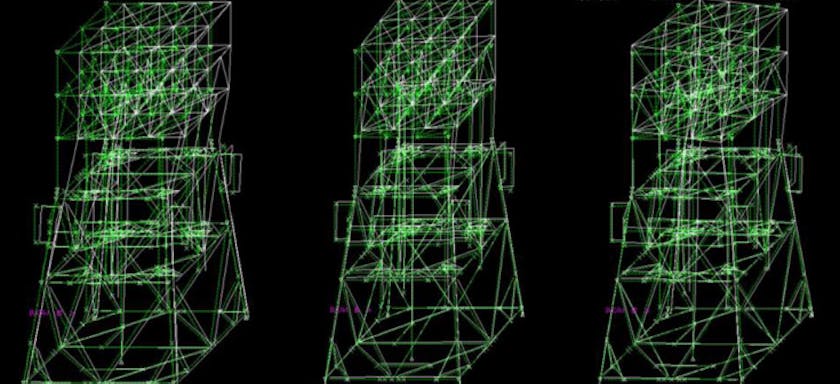

For ultra-deepwater subsea wells, a riser system is required to conduct completion, intervention/workover and end of life activities. For ultra-deepwater riser systems with high temperature and pressure requirements, the intervention riser system often requires vessel interface optimization to achieve acceptable design response. The upper riser can be configured in several different ways, each with its own benefit from a safety, risk and performance perspective. This paper compares the riser response for various vessel interfaces for ultra-deepwater applications.

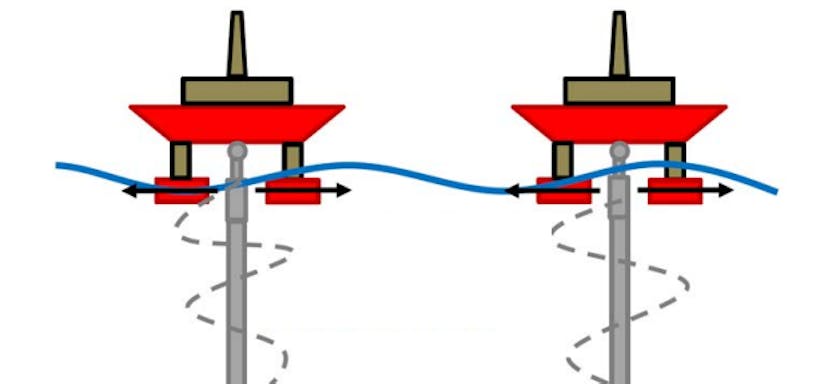

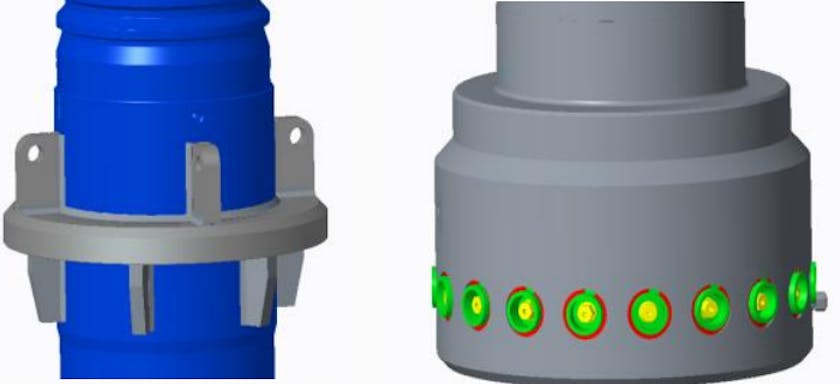

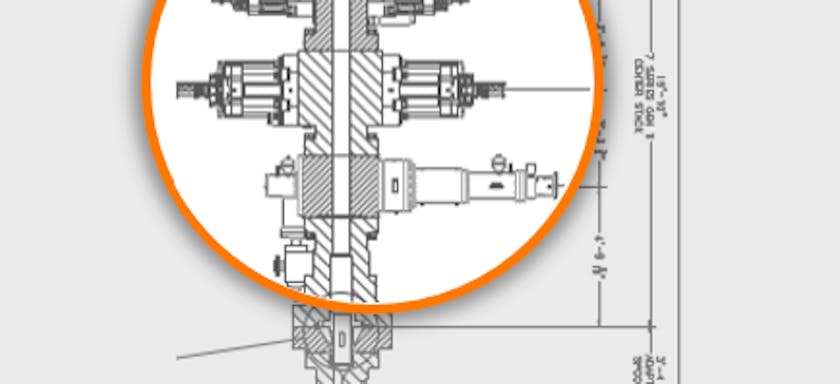

As discussed above, intervention riser structural response is sensitive to the riser configuration at the vessel interface. For a typical intervention riser, due to ultra-deepwater and high tension requirements, the functional tension load may utilize up to 40% of yield strength thus decreasing the capacity available to accommodate bending and pressure loads. Vessel operators have options to modify the system configuration to improve the strength and fatigue response of the riser. The different vessel interface options include the tension lift frame (TLF) to vessel interface, the top tension application method and the use or otherwise of a surface tree dolly. Upper riser assembly (URA) loads may be optimized by use of rotary wear bushings, a cased wear joint assembly or flexjoints as a part of the stack-up.

The various riser-vessel interface options are evaluated and compared in this paper. This paper highlights the riser design challenges for ultra-deepwater applications.

Authors

Mahesh Sonawane

Technical Advisor - Drilling & Completions

About

Mahesh Sonawane is a Technical Advisor for Drilling and Completions with 2H Offshore in Houston. He has a Masters of Science in Mechanical Engineering from Texas A&M University, Mahesh had over 15 years experience in global riser analysis and specialized in drilling and completion risers, HPHT equipment and riserless well intervention systems for offshore applications.

Expertise

Rohit Vaidya

Senior Engineering Specialist

About

Rohit Vaidya is a Sr. Engineering Specialist at 2H Offshore Engineering in Houston, US with 10 years’ experience in riser, conductor and subsea engineering. His experience includes engineering design of offshore riser systems, integrity management of platforms, conductors and risers and fatigue analysis of drilling riser systems. He specializes in drilling and completion riser analysis and worked on several drilling and completion projects all around the globe. He holds a Master’s degree in Mechanical Engineering from Oklahoma State University in USA.

Expertise

Elaine Whiteley

Senior Engineer

About

Elaine is a senior engineer in 2H’s Houston office. She holds a master’s degree in Structural Engineering from Heriot Watt University and has 12 years’ experience in the energy industry. Elaine is a Chartered Engineer and Member of the Institute of Civil Engineers. Her experience focuses on a range of different riser designs, shallow water conductor systems and subsea structural analysis. Elaine started her career with 2H in Aberdeen before relocating to 2H Houston in 2019 to broaden her experience to different riser systems. She has held numerous project management and technical roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigation, shallow water platform conductor integrity management and seawater intake riser design.

Jonathan Rourke

Helix