Comparison of Riser Fatigue Methodologies based on Measured Motion Data

EVENT: OTC

1 May 2016

In-situ riser structural monitoring has been used by a number of operators and drilling contractors to support drilling operations. The measurements have been used to understand the level of accuracy present in the up-front fatigue analysis and to confirm the integrity of the drilling systems, especially during extreme environmental events. However, the field data analysis requires detailed understanding of drilling riser modeling, loading conditions, operations, sensor characteristics and signal processing. Several methods have been developed to calculate stresses and fatigue damages in the riser using measured motion data. Careful selection of the analysis approach will determine the system configuration and validity of the measured results.

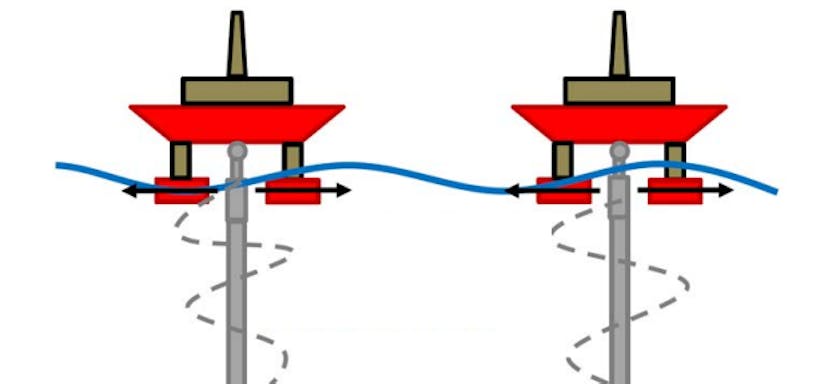

Mode shape matching has been widely used for the data analysis where riser response is dominated by Vortex Induced Vibration (VIV). Another riser fatigue method has been recently developed and is based on analytical transfer functions used to convert measured accelerations into curvature. Another method considers FEA-based transfer functions. Some of these methods perform fatigue calculations in time domain while some others in frequency domain.

Each method exhibits benefits and limitations depending on the characteristics of the measured riser response. Selecting the most appropriate fatigue methodology depends on the riser response and instrumentation system design.

In this paper, three fundamentally different riser fatigue methods utilizing measured motion data are described and compared with each other. The advantages and disadvantages of each approach are evaluated and recommendations are provided for when each method should be considered.

Authors

Bulent Mercan

Technical Advisor - Integrity Monitoring

About

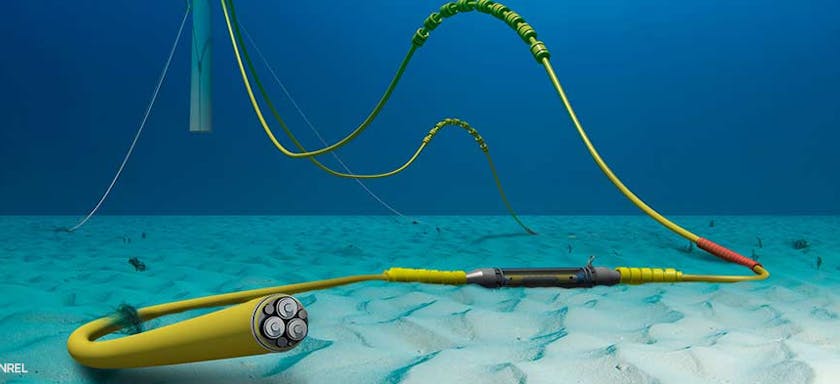

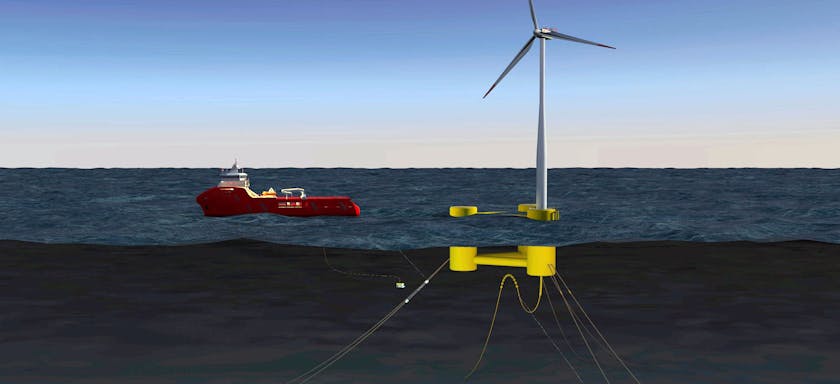

Bulent is a technical advisor based in 2H’s Houston office where he is responsible for the development, management, and growth of integrity monitoring programs for subsea structural systems in the oil, gas and renewable sectors. Bulent has held numerous project management and technical leadership roles on a variety of projects like Measurement-based Wellhead Fatigue JIP, integrity monitoring (including drilling risers, wellheads, SCRs, TTRs, subsea jumpers), the structural and thermal assessment of power cables, and the analysis of seawater intake risers as part of decarbonization strategies. Bulent is a registered Professional Engineer in Texas and holds a Ph.D. in structural engineering from the University of Minnesota.

Insights

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Yenny Chandra

Engineering Specialist

About

Yenny has over 9 years of experience in offshore riser systems including Steel Catenary Risers (SCR), Top Tensioned Risers (TTR), drilling risers, and completion risers. She has been involved in design and analysis of riser systems, structural monitoring, and riser life extension projects. Her recent work has been focusing on using measurements to verify industry-standard modelling practice in fatigue assessment of SCRs and drilling risers. Yenny is a registered Professional Engineer (PE) in Texas and holds a doctoral degree from Rice University, Houston.