Integrity, Life Extension & Monitoring

Digital Twin

This service is provided collaboratively by 2H and Clarus Subsea Integrity, a division of 2H.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Dharmik Vadel

Vice President, Clarus Subsea Integrity, USA

About

Dharmik is Vice President of Clarus Subsea Integrity and has led the company since it's inception in January 2015, responsible for business management and global growth of the organization.

Dharmik has over 18 years of experience in the development, implementation and management of integrity programs. He has led the development of digitalisation services with products such as iCUE - Clarus’ cloud-based IM software, Inspection APP - for digitalising inspection workflows,and Anomaly APP – image recognition AI for visual anomaly detection. His areas of expertise include digital solutions for asset lifecycle, corrosion management programs (RBI), delivering risk mitigation solutions, and life extension studies. Dharmik holds an M.S. in Environmental Engineering from Oklahoma State University and a bachelor’s in Civil Engineering from REC Calicut India.

Shankar Sundararaman

Senior Principal Engineer

About

Shankar Sundararaman is a Senior Principal Engineer with 2H Offshore. He has over 15 years' experience in the oil and gas industry, including design and numerical analysis of riser systems (drilling and completion risers, TTRs, SCRs, flexible risers), tendons, jumpers (rigid and flexible), machine learning (including digital twins) and cloud computing, structural health monitoring, drill string systems, drilling engineering analysis, and vibration analysis. He also has over 20 years engineering and R&D experience with numerical analysis, scientific computing, and finite element analysis. He has 5 granted patents, over 25 publications in international journals, conferences, and book articles, and presented at several international conferences. He has an undergraduate degree in Naval Architecture from IIT Madras, masters and doctoral degrees in Mechanical Engineering from Purdue University and is a Licensed Professional Engineer (Naval Architecture) in the State of Texas.

Insights

Craig Dickinson

Engineering Specialist

Craig Dickinson

Engineering Specialist

Digital twins provide a complete overview of the condition of an offshore system to proactively manage integrity and address issues before they happen.

What is a Digital Twin?

Simply put, a digital twin is a virtual replica of an actual offshore system. It significantly reduces the time it takes to generate a health check of an asset and is used as an operational decision-making tool for integrity management and life extension.

Where a conventional approach using FEA to identify stress on a system may take a couple of months to complete, the same results can be achieved in four hours using a digital twin.

2 months

Conventional FEA Analysis

4 hours

Digital Twin

How Does a Digital Twin Work?

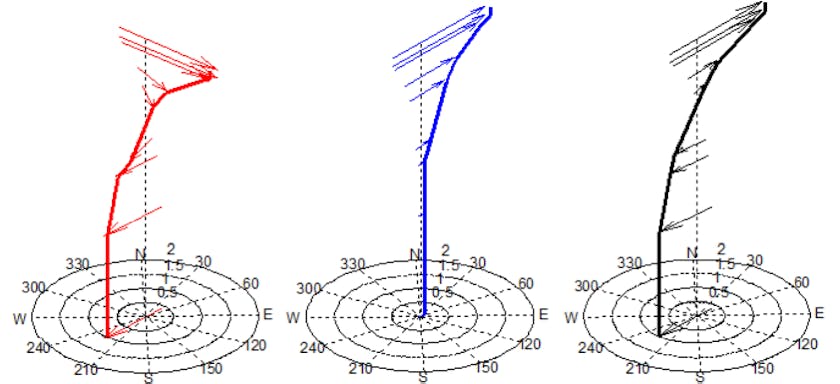

A digital twin relies on machine learning and initially we use the output from FEA or existing field data to train it to represent the real-life system. We have developed algorithms that track stress and fatigue in near real time, which means no waiting on monitoring data or time-consuming analysis to get a picture of the system’s condition. This technology can be applied to a wide range of offshore applications to make better use of measured offshore data such as detecting mooring line failure from the behaviour of changes in vessel position, and dynamic drift off watch circles for DP drilling vessels based on the prevailing weather conditions.

Development of a Digital Twin

To develop a digital twin, we work with clients to gather field data that is already available. If needed, we can help specify a similar system that will provide the input data to develop the digital twin. Sometimes it is also necessary to place monitoring devices at key locations on the real system to capture complex local response. This data is then applied to the entire system, creating a comprehensive virtual structural monitoring system.

The digital twin can be cloud based or deployed on the edge, creating a customisable and user-friendly interface to process field data and visualise real-time stresses and fatigue damage accumulation over the life of field.

Project Experience

Brazil client – Riser drift off app

LLOG - Flowline fatigue digital twin

Tullow - Flexible riser fatigue digital twin

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Dharmik Vadel

Vice President, Clarus Subsea Integrity, USA

About

Dharmik is Vice President of Clarus Subsea Integrity and has led the company since it's inception in January 2015, responsible for business management and global growth of the organization.

Dharmik has over 18 years of experience in the development, implementation and management of integrity programs. He has led the development of digitalisation services with products such as iCUE - Clarus’ cloud-based IM software, Inspection APP - for digitalising inspection workflows,and Anomaly APP – image recognition AI for visual anomaly detection. His areas of expertise include digital solutions for asset lifecycle, corrosion management programs (RBI), delivering risk mitigation solutions, and life extension studies. Dharmik holds an M.S. in Environmental Engineering from Oklahoma State University and a bachelor’s in Civil Engineering from REC Calicut India.

Shankar Sundararaman

Senior Principal Engineer

About

Shankar Sundararaman is a Senior Principal Engineer with 2H Offshore. He has over 15 years' experience in the oil and gas industry, including design and numerical analysis of riser systems (drilling and completion risers, TTRs, SCRs, flexible risers), tendons, jumpers (rigid and flexible), machine learning (including digital twins) and cloud computing, structural health monitoring, drill string systems, drilling engineering analysis, and vibration analysis. He also has over 20 years engineering and R&D experience with numerical analysis, scientific computing, and finite element analysis. He has 5 granted patents, over 25 publications in international journals, conferences, and book articles, and presented at several international conferences. He has an undergraduate degree in Naval Architecture from IIT Madras, masters and doctoral degrees in Mechanical Engineering from Purdue University and is a Licensed Professional Engineer (Naval Architecture) in the State of Texas.

Insights

Craig Dickinson

Engineering Specialist