Understanding HPHT Riser Design Limits for Deep and Ultra Deep Water

EVENT: World Oil HPHT Conference

1 Sep 2019

This presentation covers:

Introduction

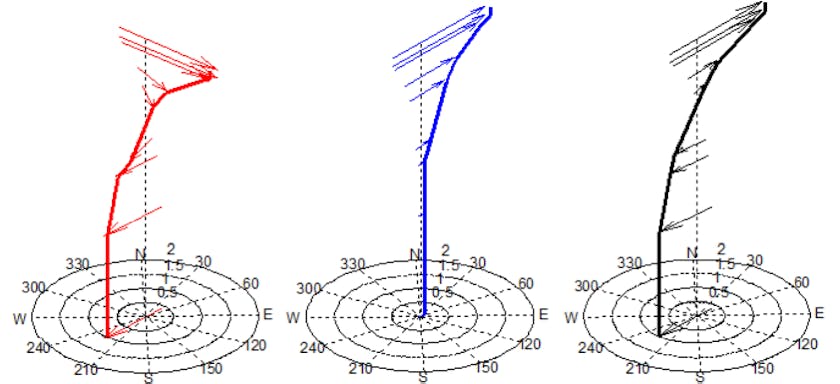

Riser Configurations

HPHT Riser Design Drivers

Technology Readiness Status Heat Maps

Summary

Authors

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Weihua Mo

Principal Engineer, Houston

About

Dr. Weihua Mo joined 2H Offshore in 2011, after earning his Ph.D. degree in Civil Engineering from Cornell University, US. Today, he serves as a Principal Engineer at 2H Offshore's Houston office. Dr. Mo has significant experience in the design and analysis of deepwater pipeline and riser systems, with a focus on steel catenary risers, steel lazy wave risers, and top-tensioned risers. He has served as analysis lead or technical lead on numerous projects ranging from Pre-FEED through detailed design, such as Chevron Big Foot, Total Moho Nord, Total North Platte, and ExxonMobil Julia.

Expertise

Pete Padelopoulos

Senior Principal Engineer, USA