Drilling Riser Structural Damping Test

EVENT: ISOPE

1 Jun 2012

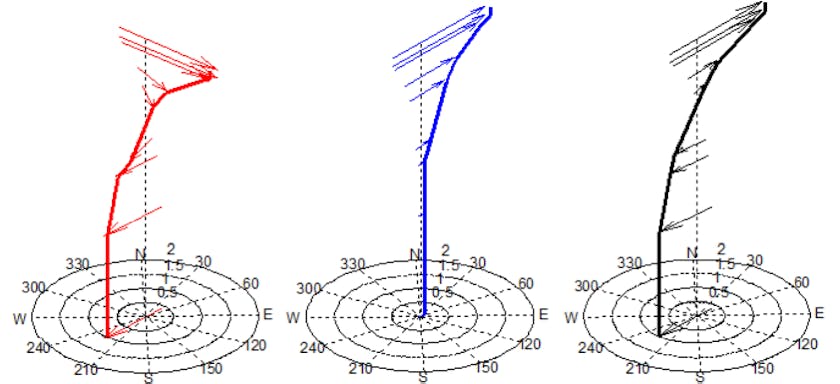

Existing drilling riser design and vortex induced vibration (VIV) analysis methodology rely on critical assumptions such as damping coefficient to represent the complex dynamic behavior. Comparing field measurements with analytical software results show a fatigue damage bias and hence over conservatism in riser design.

One possible explanation for this is the structural damping inherent in drilling riser systems with choke and kill line and buoyancy. Full scale testing in air was initiated by DeepStar® to quantify and compare structural damping of bare and buoyant drilling riser joints. The objective was to develop guidelines on structural damping value to be utilized in drilling riser design, particularly VIV. This paper presents the results of full scale testing performed on a number of drilling riser pipe configurations to determine the effect that length, mode, frequency, choke and kill lines and buoyancy modules have on structural damping. Results from the full scale testing indicated that there was more structural damping than first expected.

Author

Pete Padelopoulos

Senior Principal Engineer, USA

Pete Padelopoulos

Senior Principal Engineer, USA

Insights

Michael Ritchie

Mike Tognarelli

BP

Jim Chitwood

Deepstar