Projects

Turnkey Completion Riser Weak Link Joint Design and Delivery

2H designed and delivered a complex and critical custom hardware solution as an enhanced safety mechanism for an operational completion riser system.

Material Specification and Testing

To have the specially designed fasteners fail at the desired break load, control of the fastener material properties was essential. This required careful selection of the raw material concerning material chemistry and mechanical properties combined with mechanical tensile to acquire the desired yield and tensile properties of the studs. ASTM A370 tensile samples with a half-inch diameter were used for mechanical testing during fabrication, and multiple full-scale tensile tests using the 2H-designed weak link specialty stud geometry were performed. All tensile testing was performed on a significant sample size, to validate that the material could achieve a target break load and to determine a probability level. All information acquired from testing was used as input into the analytical models to finalise the design of the specialty stud to ensure it fails at the desired loading considering all twelve studs in the weak link connection.

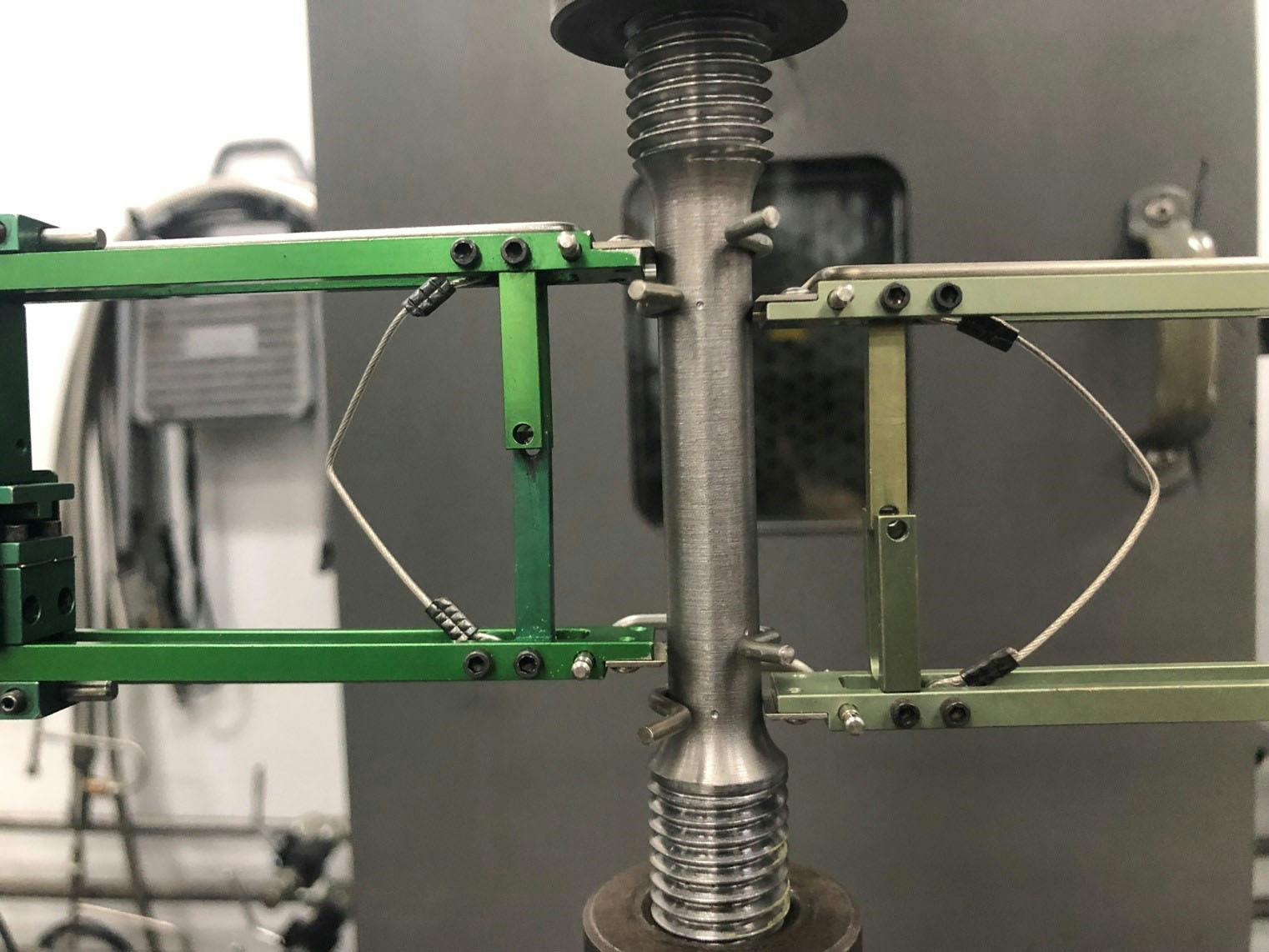

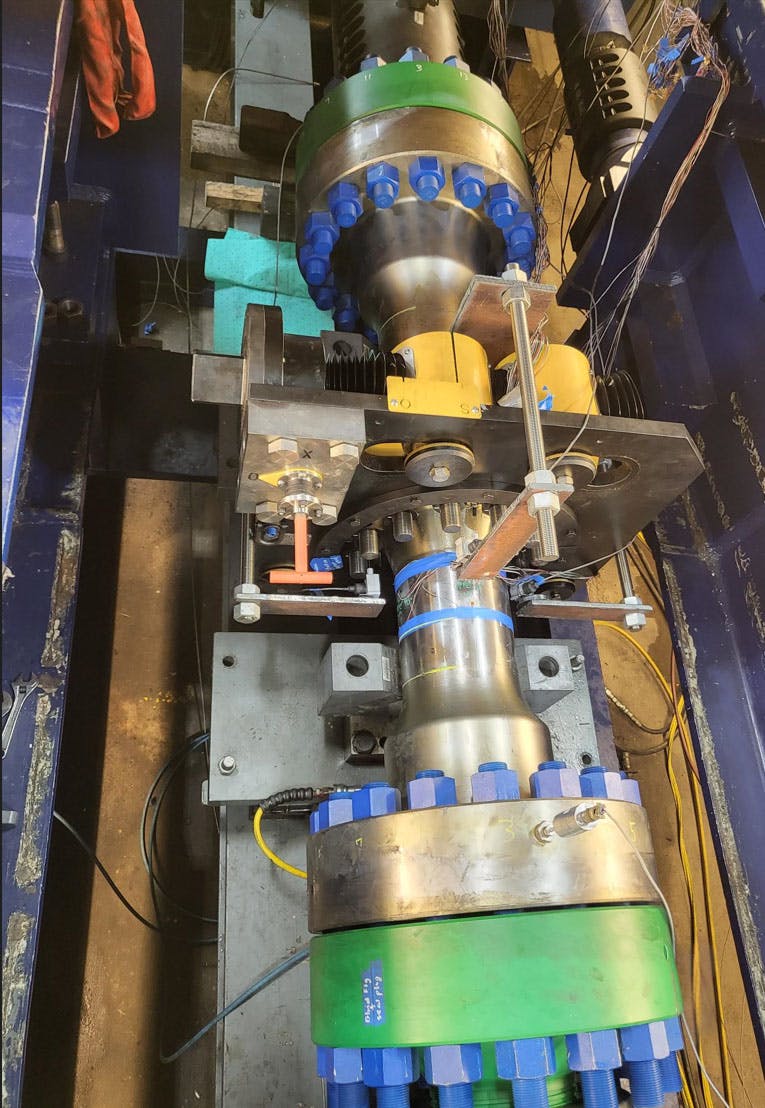

Qualification Testing

To ensure the design would perform as expected, 2H conducted an extensive qualification testing programme. This included the fabrication of a complete full-scale weak link joint which was fitted with strain gauges to monitor the response during testing. Multiple combined load cycles including pressure, tension and bending representing normal, extreme, and accidental loading conditions were applied to the test joint until a final load was applied to achieve weak link activation. During testing, the weak link joint response under load was as predicted by FEA methods and the actual failure load of the twelve fasteners was within 1% of the analytical model prediction, a result that determined the design to be suitable for its intended purpose.