Background

Tullow Ghana’s Jubilee field is located in the West Cape Three Points block, offshore Ghana. The development consists of subsea production systems and SURF equipment tied back to an FPSO. Rigid well jumpers provide an interface for transporting fluids between the wells and the subsea structures.

Tullow wanted to fabricate and install new and replacement jumpers on the Jubilee field using prefabricated jumper kit left over from another project. Tullow contracted 2H to assess the suitability of the prefabricated rigid jumper kits and line pipe materials.

2H’s Role – Assessing Jumper Suitability

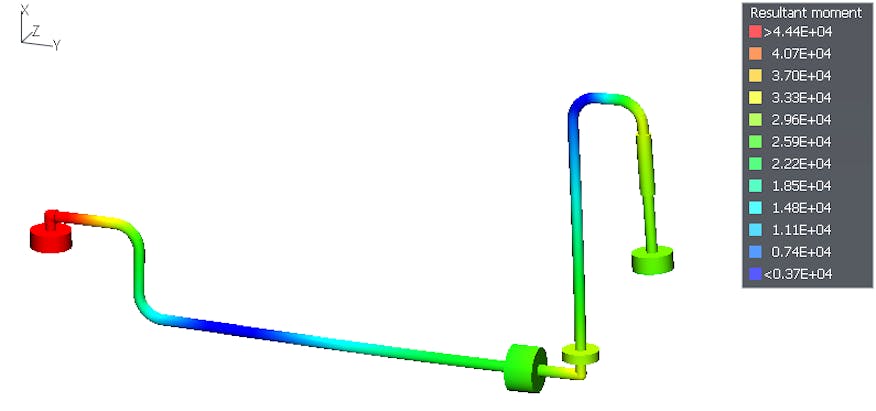

The 2H team started by reviewing jumper specifications to determine the suitability of the line pipe for jumper application. We performed strength and VIV analysis to confirm that the jumper design met the necessary design codes. We evaluated the existing water injection and production jumpers in the Jubilee field, then optimized the jumper shape and configuration to achieve a working jumper structure with the available equipment.