Capitalising on Flexible Pipe Design Conservatisms

Territorial philosophies towards the sharing of information in the flexible pipe community are costing operators time, money, and headaches. Members of our industry are justifiably hesitant to share their valuable intellectual property; however, the resulting lack of collaboration and transparency has made the market slow to adopt advancements in riser engineering technology that can benefit design, operation, and life extension decisions.

3 Jan 2018

Author

Chris Brachey

Senior Engineer, Houston

To bring these benefits to operators, independent engineering firms have developed proficiency in detailed flexible cross-section assessment and are incorporating their own engineering expertise. This can be applied today to help extend the service life of in-field equipment by capitalising on design level conservatisms in existing flexible pipe.

Unbonded flexible pipes are complicated structures comprised of multiple layers varying in material, thickness, shape, and function. How these layers interact and respond to different stimuli is an area of constant study. Because of the complexity of the structural assessment, assumptions are often made to simplify the structural analysis while trying to err on the side of conservatism. By removing these simplifying assumptions in a more detailed engineering assessment, conservatism can safely be removed, allowing operators to extract the true value of their brownfield flexible assets.

What common simplifications can we take advantage of?

The most obvious simplification in a typical flexible riser design is the application of ocean environments as conservatively large regular interval waves (regular wave approach). A regular wave methodology is commonly employed in flexible pipe analysis because of complications associated with applying more complex waves in flexible pipe local cross-section finite element programs. In reality, wave elevation is more accurately represented by a probability distribution of waves of varying height, period, and direction (irregular wave approach). The more accurate irregular wave approach takes advantage of the distribution of energy between different wave frequencies and directions to decrease the estimated fatigue damage of offshore environments.

In addition to environmental modelling, the design phase of flexible pipe makes conservative assumptions for fluid temperature and pressure to allow for uncertainty in the operating requirements over the life of field. Due to the complex friction and stiffness interactions between unbonded flexible pipe layers, the operating fluid assumptions can significantly influence the response of the pipe. For brownfield risers, the structural response of the pipe can be re-evaluated with historical pressure and temperature data allowing design conservatism in operating fluid properties to be removed.

How can flexible pipe assessments be refined?

The Norwegian Research Council, in collaboration with the Testrig joint industry project, released a flexible pipe finite element analysis tool called BFLEX in 2001. The analysis methodologies implemented in the software have been the focus of numerous conference papers and have been rigorously qualified against full-scale testing programs to meet the requirements of API-17B, the API Recommended Practice for Flexible Pipe. Combining BFLEX’s flexible pipe modelling capabilities with speciality in-house riser software packages and optimised computing infrastructure, large numbers of irregular wave analyses can be conducted quickly, removing the need for modelling simplifications and conservatisms.

How much can a detailed assessment improve fatigue life?

Wave theory application is typically considered to influence the fatigue response of a steel riser by a factor in the range of 2 to 3. However, the nonlinear response of unbonded flexible pipe to environmental loading makes application of a standard factor inappropriate. In order to evaluate the effect of the two different wave theories on flexible riser fatigue response, two separate wave fatigue assessments are performed for the same riser; one using the regular wave approach and the other, the irregular wave approach. For our test case riser, the irregular wave approach is observed to increase the calculated fatigue life by a factor of 2.0 to 10.0 for the different fatigue critical layers.

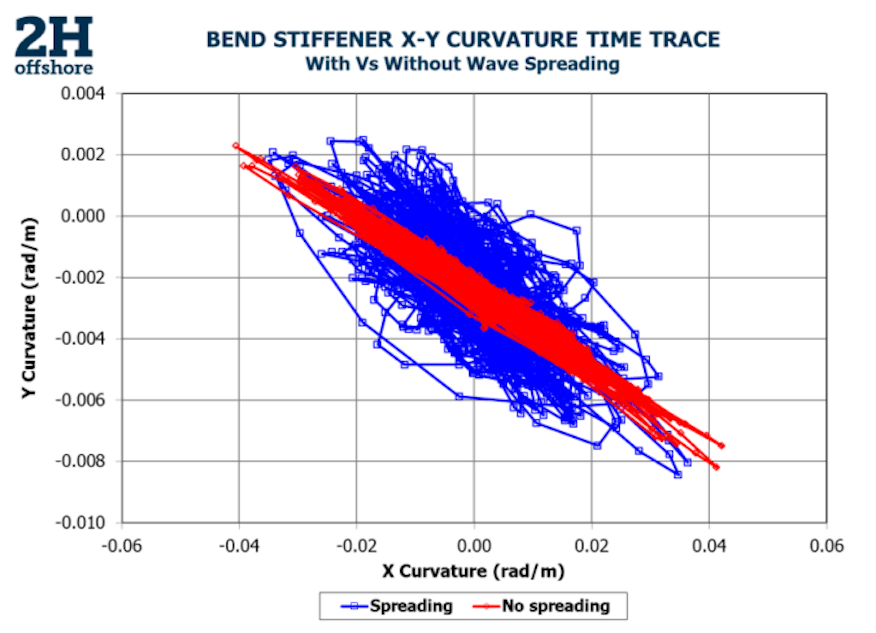

Wave directional spreading is another form of wave complexity typically excluded from flexible riser assessments. To cut down on computational time, complex seastates with varying wave headings are commonly simplified to single, averaged headings. Evaluation of our test riser with and without wave spreading found that wave spreading distributes curvature cycles around the circumference of the flexible cross-section as shown in Figure 1. Spreading of the curvature distributes the fatigue damage away from the critical location onto areas of lower damage and thereby decreases the maximum damage accumulation. For our test case, the effects of wave spreading are found to increase fatigue life by a factor of 1.7 to 2.9 for the different fatigue critical layers.

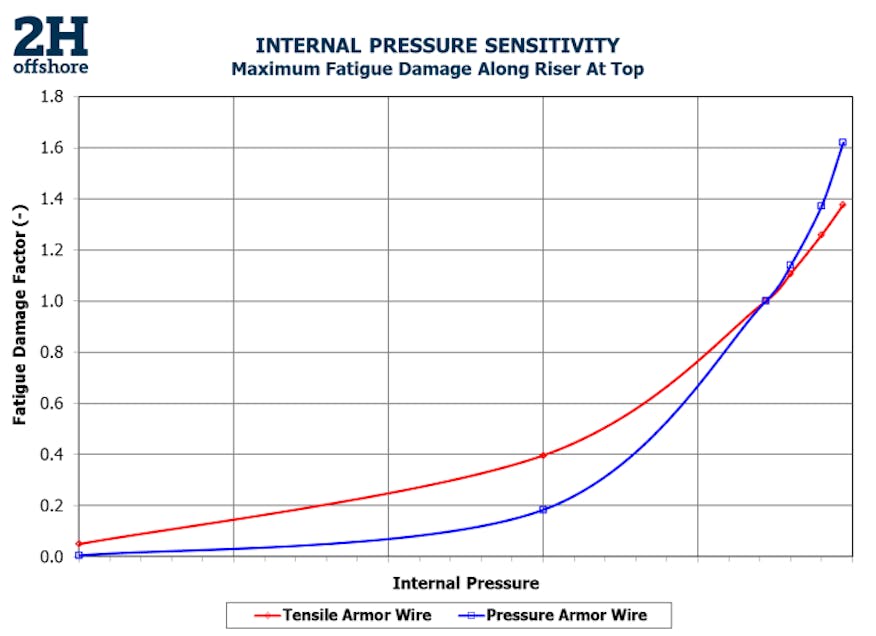

A flexible riser’s response to external loading is highly dependent on the friction interaction between flexible cross-section layers created by internal and external pressure. Since internal pressure is a somewhat controllable variable in field operation, it provides an opportunity to influence the response of flexible risers. A study evaluating the effect of varying internal pressure on our test riser revealed an exponential nonlinear trend in fatigue damage at high internal pressures as shown in Figure 2. This finding suggests that risers designed for high internal pressures and subsequently operated in less onerous conditions present a great opportunity for life extension.

The above-mentioned conservatisms represent only a sample of the simplifications implemented in typical flexible pipe design that can be removed in more detailed fitness for service or life extension assessments. As observed in our test cases, these common design conservatisms can be exploited to significantly extend the fatigue life of existing flexible pipes by two times or more.

Summary

The complexity of flexible pipes’ inter-layer interactions has led to the use of simplified and conservative analytical methodologies for the standard design of flexible pipes. Through the combination of qualified flexible pipe global and local analysis software, riser engineering expertise, and optimised computing infrastructure, independent engineering firms such as 2H can eliminate many of these simplifications. By doing so, and leveraging operational data history, operators have the opportunity to safely extend the life of equipment and extract the true value of their flexible pipe assets.

For more information on flexible pipe assessments, please contact Chris Brachey or Dhyan Deka at the 2H Houston office on (281) 258-2000 and for more information on our upcoming flexible riser webinar, email houston@2hoffshore.com.

Author

Chris Brachey

Senior Engineer, Houston