Dynamic HV Inter-Array Cable Configuration Design for Floating Wind: Challenges and Lessons Learned

Floating offshore wind farms are emerging as a powerful solution to harness wind energy in deeper waters, offering immense potential for clean energy generation. However, in this endeavour, the reliability and resilience of inter-array cables are paramount. Power cable failures currently account for a staggering 80% of financial losses and insurance claims in offshore wind operations, which is a concerning statistic that has drawn the industry's attention to the pressing need for improved cable reliability.

8 Nov 2023

Authors

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Luiza Ferreira

Principal Engineer

About

Luiza Ferreira has twelve years’ offshore engineering experience and currently is the Principal Engineer for renewable energy engineering activities for 2H Offshore’s California offices. She spent four years leading renewables engineering for 2H’s UK offices. She specialises in system engineering for floating and bottom-fixed offshore wind foundations and wave energy converters, and also has expertise in numerical analysis, structural design and engineering of subsea riser and conductor systems, including hybrid risers, rigid risers, drilling and completion risers, and flexible risers.

Language

Alex Rimmer

Director, UK

About

Alex is a Chartered Engineer with a first-class master’s degree in mechanical engineering from the University of Bath and has been working for 2H Offshore since 2004. Alex has significant experience in the design and analysis of drilling and production systems for deepwater and shallow water developments, most notably as lead analysis engineer for BP’s Block 31 PSVM freestanding hybrid riser design project. Alex has taken on a number of managerial roles at 2H, including technical manager of the Norwich office, where he was responsible for integrating UWG’s shallow water riser and conductor engineering team and business into 2H. He has been a director in our London office since 2011.

Language

Insights

Introduction

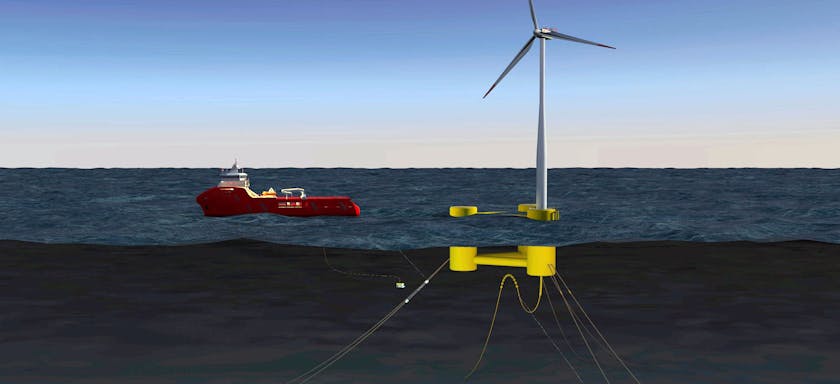

Floating offshore wind farms are emerging as a powerful solution to harness wind energy in deeper waters, offering immense potential for clean energy generation. However, in this endeavour, the reliability and resilience of inter-array cables are paramount. Power cable failures currently account for a staggering 80% of financial losses and insurance claims in offshore wind operations, which is a concerning statistic that has drawn the industry's attention to the pressing need for improved cable reliability.

The root causes of these cable failures are varied and include installation damage, manufacturing defects, inadequate design, and external damage. The industry has had some success in addressing these issues for static cables used in fixed offshore wind farms. Still, the challenges become considerably more complex when it comes to dynamic cables used in floating offshore wind applications. In this blog, we will look into the intricacies of designing high voltage inter-array cables for floating offshore wind and the lessons learned from this evolving field.

Dynamic Cable Technical Specifications

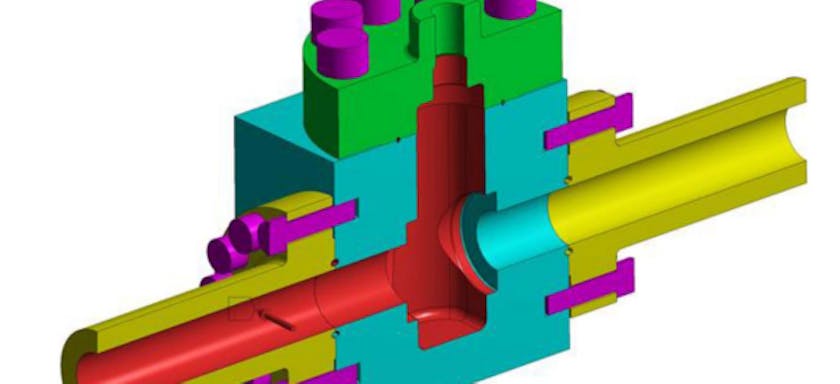

Dynamic cables used in floating offshore wind farms are subjected to unique and demanding conditions. These cables are designed to withstand the floater dynamic motions and harsh marine environments, and their technical specifications vary significantly. They typically include:

Voltage Rating: 66kV

Cable Conductor Cross Sections: Ranging from 150mm² to 1,200mm²

Cable Configuration Design: Shallow Water vs. Deep Water

When designing inter-array cables for floating offshore wind, the distinction between shallow water and deep water is crucial.

It is a misconception that developing an inter-array dynamic HV power cable in shallower waters is easier than in deeper water depths. The shorter a power cable is, the less capable it is of absorbing the motions occurring at the floater and the higher the bending loads are.

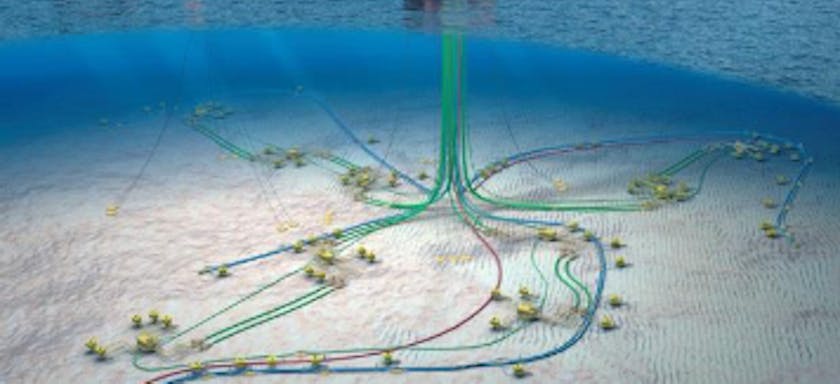

Shallow water cable configurations can draw valuable insights from the design of umbilicals used in the oil and gas industry. However, most of the commonly adopted configurations from oil and gas shallow water projects are complex (e.g., include mid-water arches) and therefore are not ideal for floating offshore wind due to high costs.

It is essential to note that floating wind presents a distinct set of challenges, with hundreds of cables being deployed in comparison to the oil and gas industry, which typically involves only a few umbilicals.

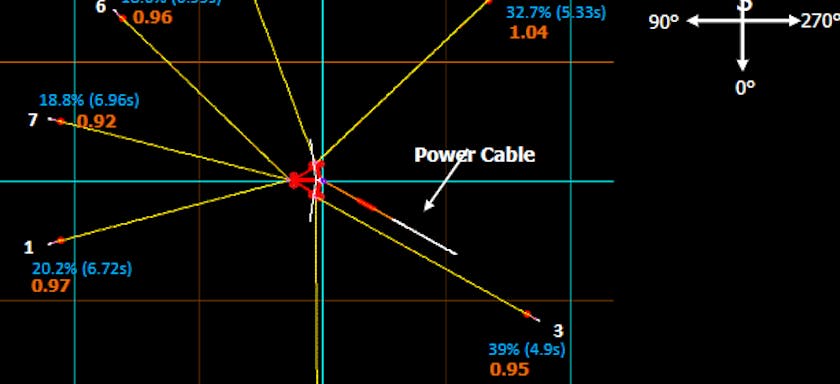

Design Requirements and Parameters

To ensure the reliability and resilience of these dynamic cables, engineers must account for a range of challenging conditions and parameters. These conditions include:

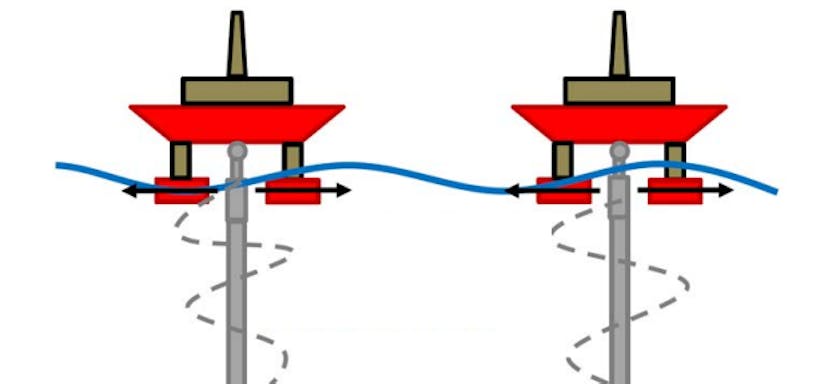

Large floater lateral motions (approximately 30% of water depth)

Floater dynamic rotations (8-12 degrees)

High wave heights (up to 25 meters Hmax)

High currents (> 1.0m/s)

Variations in marine growth over the life of the system

© 2H Offshore

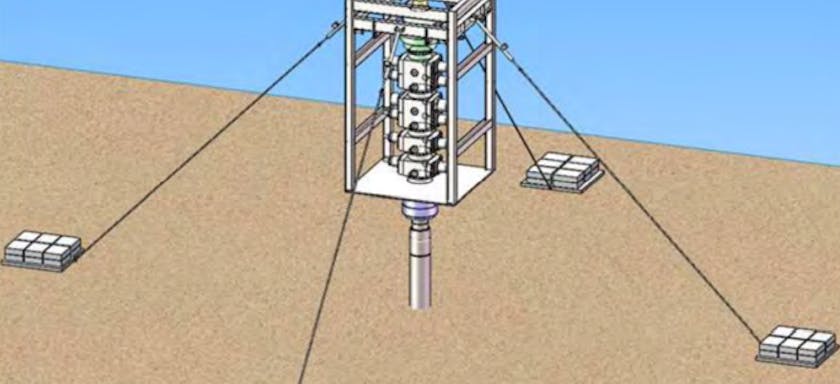

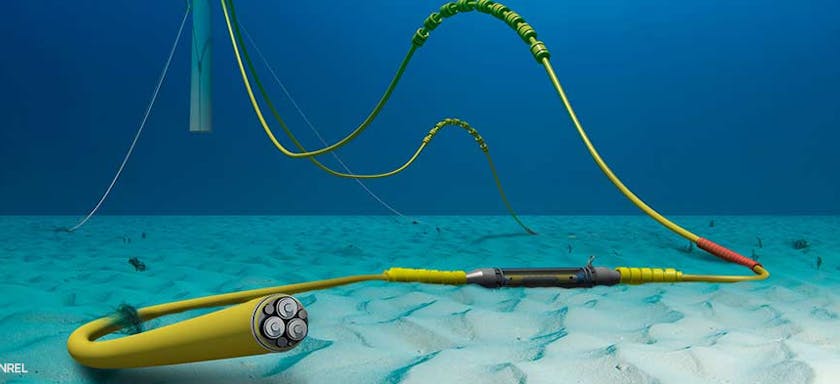

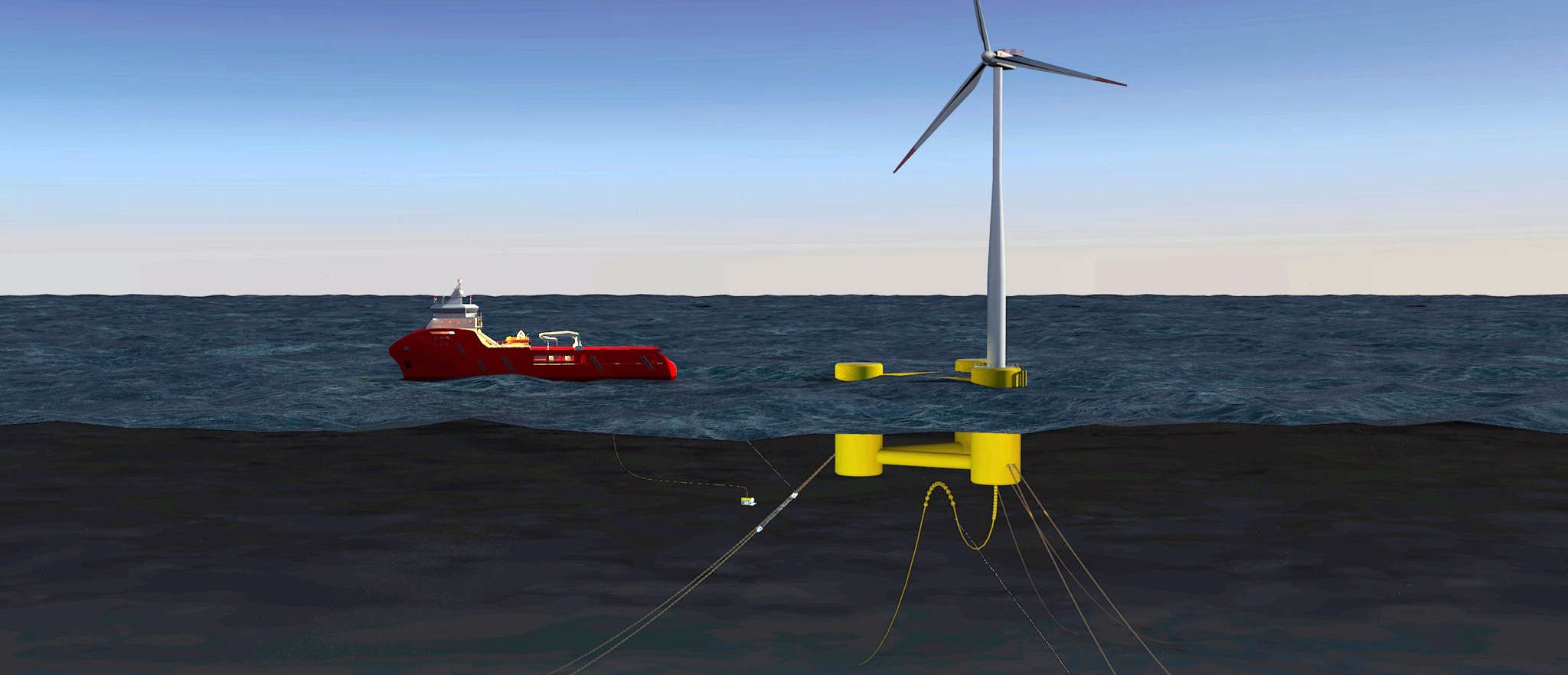

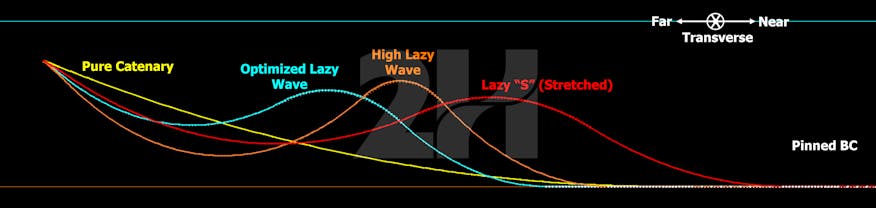

Simultaneously, it's essential to meet design requirements such as respecting structural limits, minimum bend radius (MBR), maximum tension, and compression thresholds. If a lazy wave configuration like that shown above is used the sag bend should not impact the seabed, the hog bend must maintain sufficient clearance for vessel access plus compressive loads and seabed movement at the touch-down point should be kept to a minimum. Additionally, there should be no clashing with adjacent structures, such as the floater and mooring lines.

The lazy wave system is the preferred option for very shallow waters (typically less than 100 meters in the North Sea) and the amount of buoyancy modules and their distribution play a significant role in controlling the shape of the configuration.

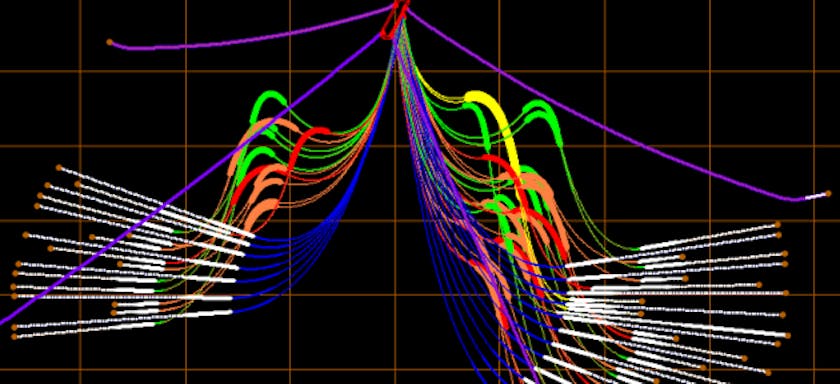

The Selection of an Optimised Configuration

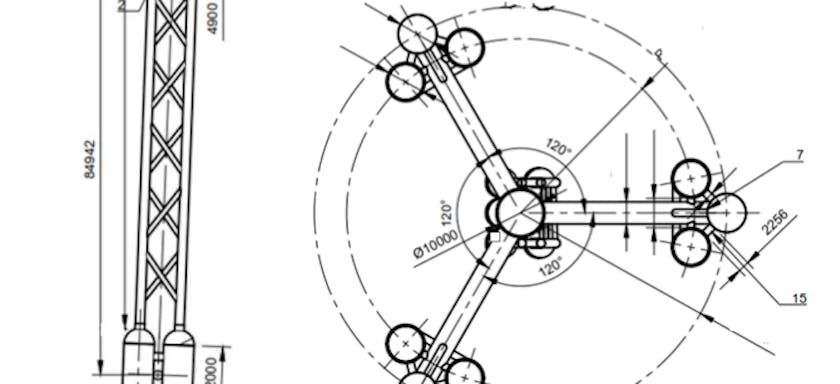

Selecting the optimum cable configuration is a meticulous process. It involves a wide range of iterations with variations in top angle, section lengths, and buoyancy modules, all while balancing competing parameters. The chosen configuration should consider the unique characteristics of the floater type, water depth, metocean conditions, and mooring design. Moreover, the cable configuration must function reliably both at the start of the system's life and at its end, considering the challenge of buoyancy water ingress and marine growth in the area.

In conclusion, the design of high voltage inter-array cables for floating offshore wind is a multifaceted process that necessitates careful consideration of environmental conditions, structural limits, and integration with the broader system. As the floating offshore wind industry continues to grow, the lessons learned from cable design will play a vital role in ensuring the reliability and sustainability of these remarkable clean energy projects. Dynamic cable design remains an ever-evolving field, with continuous innovation and adaptability being the keys to success in this sector of renewable energy.

© 2H Offshore

Authors

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Luiza Ferreira

Principal Engineer

About

Luiza Ferreira has twelve years’ offshore engineering experience and currently is the Principal Engineer for renewable energy engineering activities for 2H Offshore’s California offices. She spent four years leading renewables engineering for 2H’s UK offices. She specialises in system engineering for floating and bottom-fixed offshore wind foundations and wave energy converters, and also has expertise in numerical analysis, structural design and engineering of subsea riser and conductor systems, including hybrid risers, rigid risers, drilling and completion risers, and flexible risers.

Language

Alex Rimmer

Director, UK

About

Alex is a Chartered Engineer with a first-class master’s degree in mechanical engineering from the University of Bath and has been working for 2H Offshore since 2004. Alex has significant experience in the design and analysis of drilling and production systems for deepwater and shallow water developments, most notably as lead analysis engineer for BP’s Block 31 PSVM freestanding hybrid riser design project. Alex has taken on a number of managerial roles at 2H, including technical manager of the Norwich office, where he was responsible for integrating UWG’s shallow water riser and conductor engineering team and business into 2H. He has been a director in our London office since 2011.