Tension Loss Of Hydro-pneumatic Riser Tensioners

EVENT: OMAE

1 Jun 2013

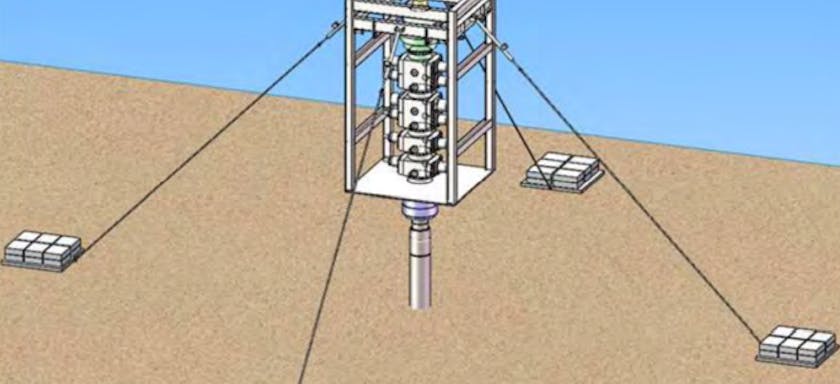

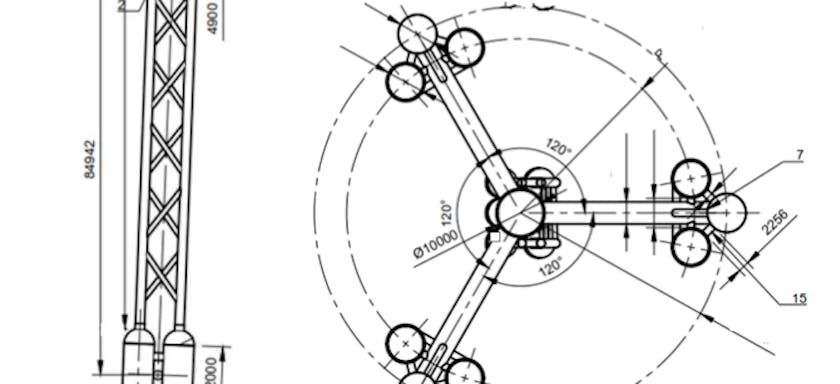

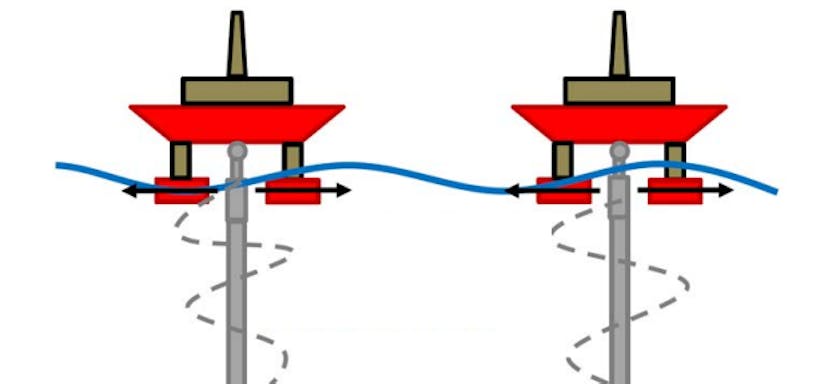

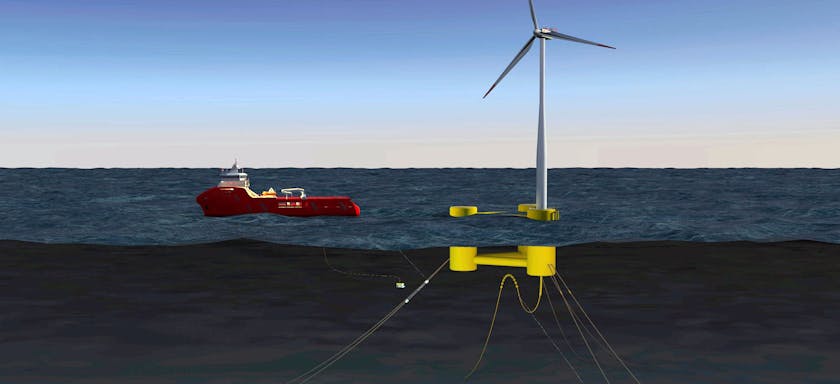

With drilling exploration extending to deeper water, the total top tension to lift a drilling riser increases accordingly. Tensioners with higher tension capacity are preferred to minimize the total number of tensioners due to space limitation on a drilling vessel. Higher tension capacity requires more advanced recoil control for emergency events.

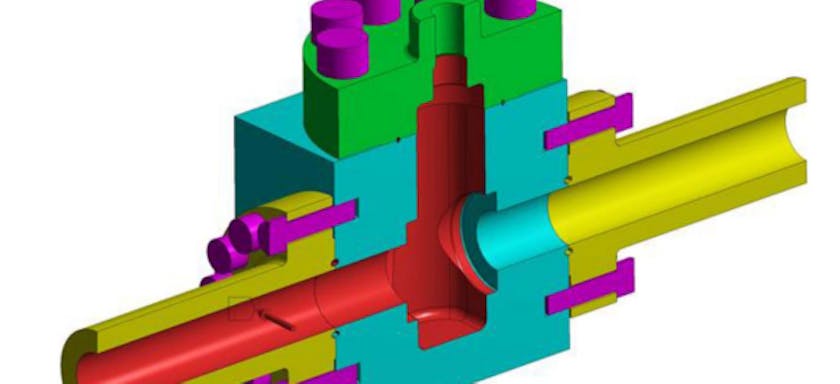

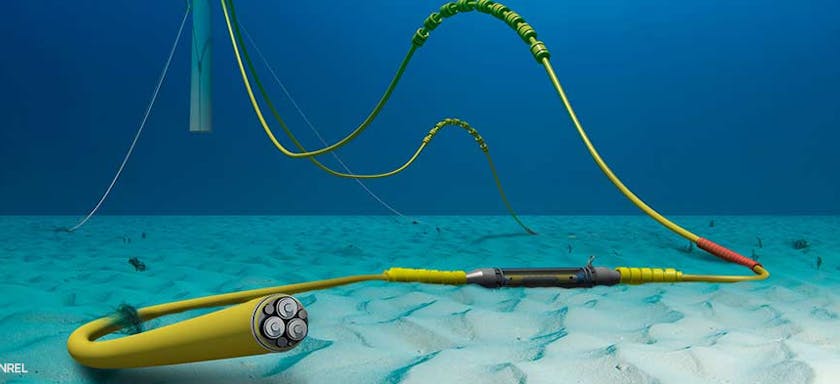

Hydropneumatic tensioners are widely used for risers with anti-recoil control in deep water, and are commonly simulated as an equivalent linear or nonlinear spring or a pneumatic system. The discrepancy between simulation and measurement calls for a model with rate dependent stiffness considering the compressibility of hydraulic oil, the interference of valve control and friction loss along piping or hose.

In this paper, the hydro-pneumatic tensioner system with anti-recoil valve control is simulated in 2HRecoil, a customized version of ANSYS Mechanical APDL, and benchmarked with commercial software DeepRiser. The tension loss due to hydraulic oil friction, mass inertia, piston-cylinder friction is evaluated with coupled riser motion. The conventional approach in simulating the hydro-pneumatic tensioner system as an equivalent pneumatic system is found inaccurate. The sensitivity of the pressure difference between the cylinder chamber and the high pressure accumulator on the gas constant is discussed. The scatter in predicting gas constant, friction and damping coefficients from measured data is explained using hydro-pneumatic approach.

Authors

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Songcheng Li

Senior Engineering Specialist, Houston