Fracture Mechanics Based Fatigue Assessment of an HPHT Valve Body

EVENT: OTC

1 May 2019

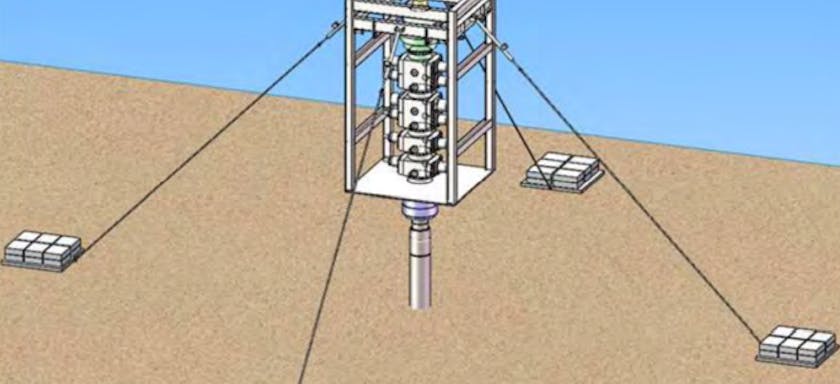

The development of HPHT oilfield equipment has typically resulted in the construction of heavy-walled designs, where the increase in rated working pressure is accommodated by an increase in sectional thickness. This manner of design, however, is limited by practical difficulties which arise in the areas of manufacturing handling/lifting, and uniformity of through-thickness material properties. Designs of more efficient size and weight may be developed by relaxing assumed design factors and hydrotest pressures, but this requires more rigorous analysis, validation, and QA measures.

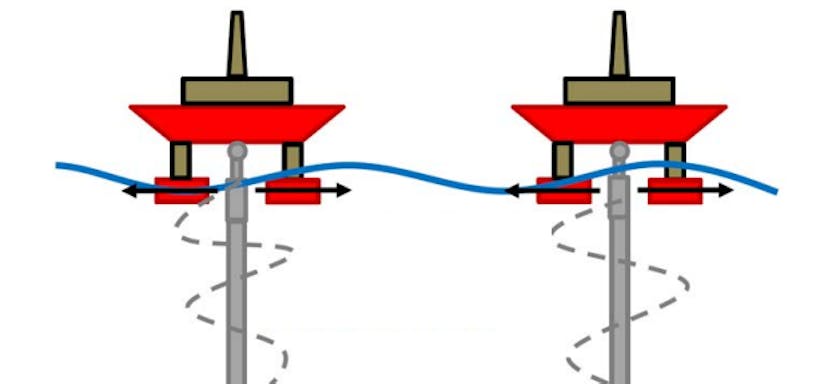

In particular, designers must address the fatigue susceptibility of HPHT equipment which, even in purely static conditions, may fail under cycles of shut-in pressure alone. These failures typically originate from

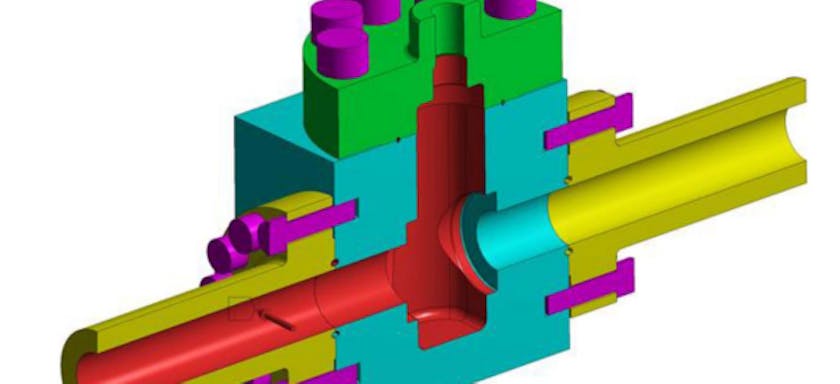

stress risers such as cross-bores, seat pockets, or transitions in bore diameter, which exhibit complex stress states under the action of internal pressure. A fracture mechanics (FM) based analysis of such features has presented a longstanding challenge to designers and analysts as general solutions for their KI and σref are not presently available.

It is therefore the objective of this paper to provide a useful methodology for conducting FM-based analysis of arbitrary geometry using the KI and σref solutions provided in API 579-1/ASME FFS-1. The method is presented in the form of a case study which describes the FM-based fatigue analysis of a seat pocket radius within a valve body. Here, the mode I behavior of a hypothetical surface-breaking, semi elliptical flaw located at the seat pocket radius is evaluated by means of 3D finite element analysis.

Authors

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Joshua Sahoo

Senior Engineer