Dynamic Plastic Deformation of Deepwater Steel Catenary Risers under Extreme Cyclic Compressive Loading

EVENT: OTC

1 May 2014

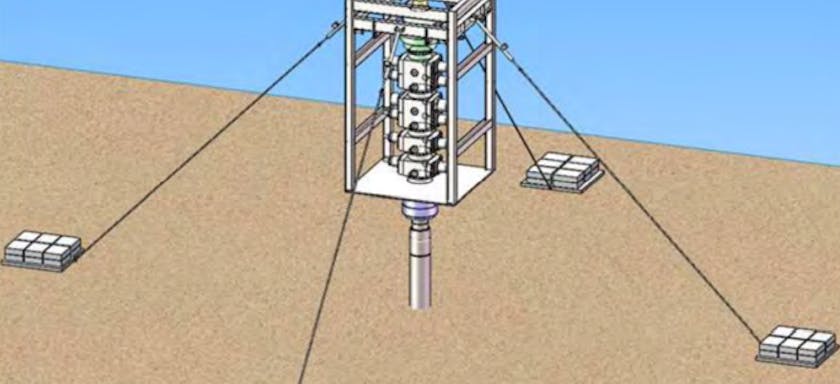

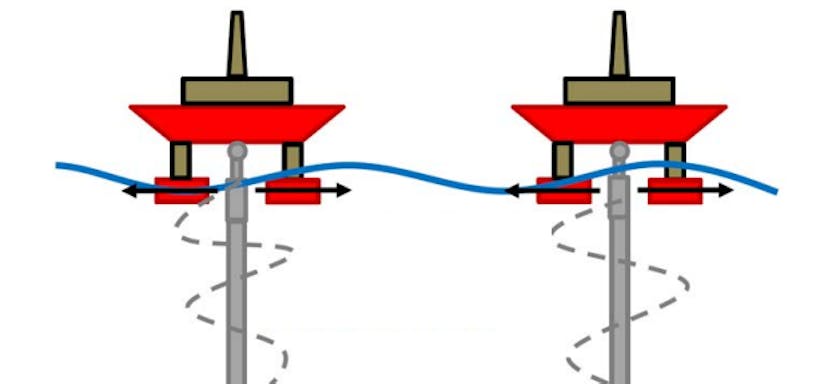

Steel catenary risers (SCR) on a large heave motion vessel are susceptible to compression in the riser touch down zone (TDZ). Dynamic compression can lead to over stress under extreme or abnormal weather conditions. The response of an SCR under compression is highly nonlinear and sensitive to various factors. However, the current available industry design codes and practices do not provide a clear guidance to address the acceptability of compression, over stress and the resulting plastic strains. In addition, the current analysis method used in industry common practice cannot accurately capture the nonlinear behavior of SCR involving accumulated plastic deformation, hysteresis effects and local buckling.

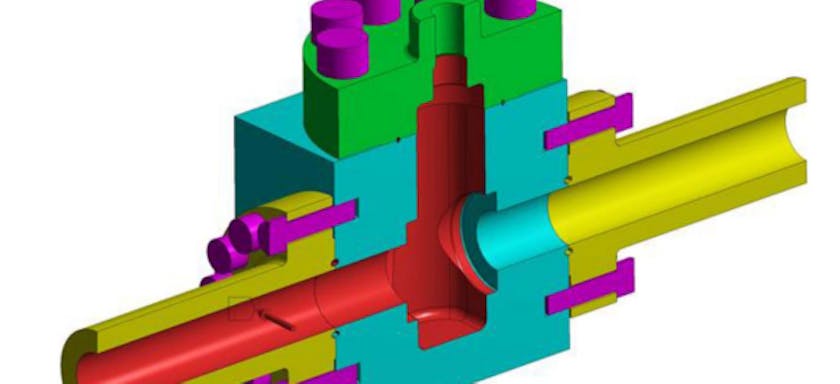

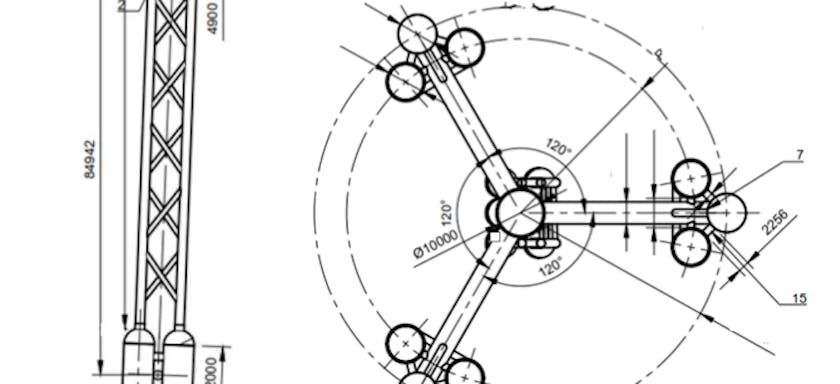

In this paper, a finite element analysis (FEA) modeling method using combined beam and solid elements is presented that enables simulation of large plastic deformation, pipe ovality and local pipe buckling in the TDZ of a deepwater SCR. The model is developed using ABAQUS. The SCR nonlinear response is examined through dynamic analysis of a deepwater SCR hung-off a semi-submersible. The key analysis results are compared with a nonlinear beam element model. Moreover, dynamic ratcheting analysis under multiple plastic strain cycles using the proposed solid riser model is conducted to understand the plastic strain accumulation and to check the acceptability of survival response of deepwater SCR under a series of severe Hurricanes in its service life.

This paper presents the methodology of evaluating the compression and plastic deformation that could be experienced by deepwater SCRs, including modeling approach, analysis results, possible failure modes, and conclusions. The impact of the study findings on the robustness and suitability of SCRs for deepwater application are discussed.

Authors

Mike Campbell

Global Director, USA

Mike Campbell

Global Director, USA

About

Mike is a Global Director and vice president of 2H’s Houston office, where he is responsible for the management of the engineering group. Mike has over 22 years of experience dedicated to riser engineering, ranging from conceptual design and feasibility to detailed design, installation, monitoring and operational integrity management for all types of riser systems and subsea equipment. He has authored numerous technical publications including fatigue analysis methods and the use of field measurements to benchmark and improve design tools. Mike is a graduate of the University of Sheffield, UK, and has a bachelor’s degree in mathematics and physics.

Guanyu Hu

Principal Engineer