Oil & Gas

Subsea Systems

2H has a holistic systems engineering approach coupled with sophisticated analysis capabilities to design the most fit-for-purpose, commercially feasible subsea solutions.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Phil Ward

Principal Engineer

About

Phil is a principal engineer in 2H’s Houston office. He holds a master’s degree in Engineering from Cambridge University and has 14 years’ experience in the oil and gas industry with various types of pipeline and riser designs, subsea structural monitoring systems, and late-life assessment techniques. Phil started his career with 2H in Aberdeen, and held the director position there before relocating to 2H Houston in 2019 with the goal of cross-populating experience with shallow and deep water systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigations, platform well design optimisation and thick-wall SCRs. Phil is a Chartered Engineer and Member of the Institute of Mechanical Engineers.

Expertise

Ryan Koska

Principal Engineer

Ryan Koska

Principal Engineer

About

Ryan is a Principal Engineer in 2H’s Houston office. He holds a Bachelor’s degree in Ocean Engineering from Texas A&M University and has been working for 2H Offshore since 2007. Ryan has significant experience in the design and analysis of production risers as well as subsea rigid jumpers, along with operability and fatigue analysis of drilling riser, wellhead and conductor systems.

Insights

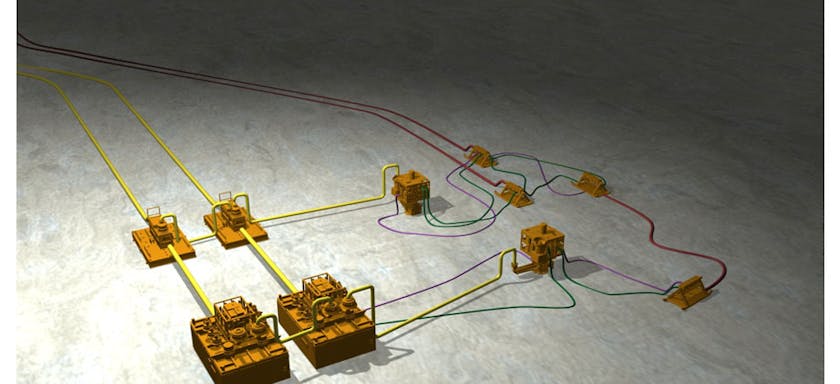

A multidisciplinary team with a complete systems approach

Our multidisciplinary team of engineers understands all the components and interfaces involved in subsea systems. We do not look at components in isolation but consider all aspects of the project from design to delivery to installation to operations. This enables us to develop the optimal solution that will maximise performance.

Adding value with data and digitalisation

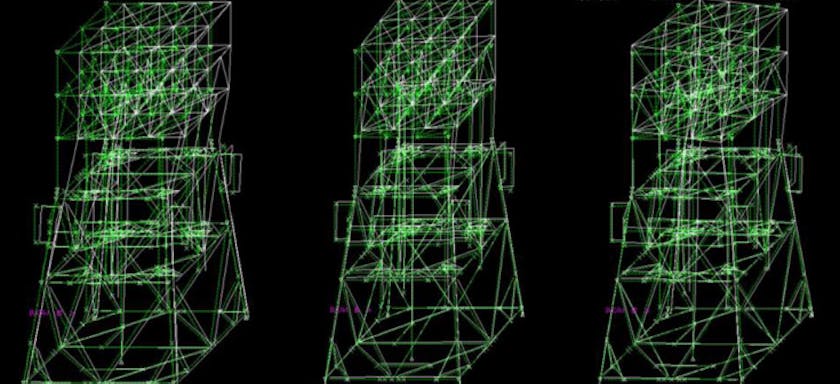

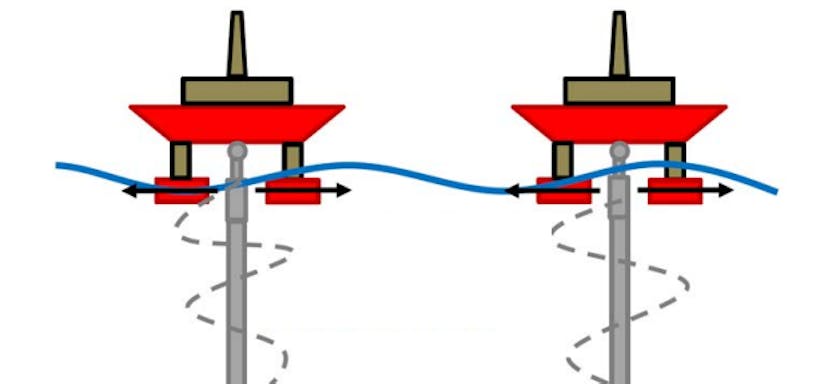

We have a track record of advancing engineering design and analysis methods to meet the offshore industry’s increasing design challenges. We have developed innovative analytical processes that increase accuracy and enable subsea solutions that were previously not feasible.

We are currently working on subsea projects that use measured data to better understand subsea system response and improve the accuracy and efficiency of our analysis and design. This approach eliminates conservatism in loads meaning we are not over-engineering unnecessarily costly solutions.

We are using machine learning for the design, integrity management and life extension of subsea structures which is helping mitigate risk and improve performance while keeping costs down. Innovative technologies such as our subsea jumper digital twin is adding value by offering improved visibility of production operations.

Key Personnel

Phil Ward

Principal Engineer

About

Phil is a principal engineer in 2H’s Houston office. He holds a master’s degree in Engineering from Cambridge University and has 14 years’ experience in the oil and gas industry with various types of pipeline and riser designs, subsea structural monitoring systems, and late-life assessment techniques. Phil started his career with 2H in Aberdeen, and held the director position there before relocating to 2H Houston in 2019 with the goal of cross-populating experience with shallow and deep water systems. He has held numerous project management and technical leadership roles on a variety of projects from concept through to detailed design, including subsea wellhead fatigue mitigations, platform well design optimisation and thick-wall SCRs. Phil is a Chartered Engineer and Member of the Institute of Mechanical Engineers.

Expertise

Ryan Koska

Principal Engineer

Ryan Koska

Principal Engineer

About

Ryan is a Principal Engineer in 2H’s Houston office. He holds a Bachelor’s degree in Ocean Engineering from Texas A&M University and has been working for 2H Offshore since 2007. Ryan has significant experience in the design and analysis of production risers as well as subsea rigid jumpers, along with operability and fatigue analysis of drilling riser, wellhead and conductor systems.