Integrity, Life Extension & Monitoring

Crisis Engineering

Rapid response engineering assessments to identify and mitigate failure issues, minimise downtime and maintain operational safety.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Pete Padelopoulos

Senior Principal Engineer, USA

Pete Padelopoulos

Senior Principal Engineer, USA

Insights

Daniel Reagan

Principal Engineer

About

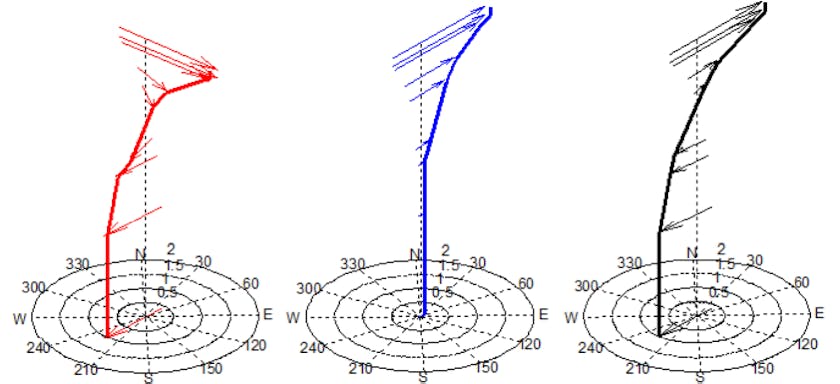

Daniel has over 17 years experience in deep water equipment design, manufacturing, testing, supply, offshore installation and inspection. As part of his early career roles and responsibilities he conducted global riser analysis, using finite element analysis (FEA) programs such as flexcom, to evaluate the strength and fatigue performance of riser system for major oil and gas operators. In addition to FEA work, spent several years designing, supplying and installing monitoring system for top tensioned riser (TTR’s), steel catenary risers (SCR’s), subsea jumpers and manifolds as well as tensioner systems.

The past 12 years have been spent overseen internal and external equipment design, manufacturing, quality, testing and delivery. Daniel has worked with and travelled to vendors throughout the world evaluating forging, machining and assembly facilities. As well as subsea equipment delivery management he have also been involved in a number of specialty subsea inspection campaign which included the development, testing and offshore inspection of critical subsea infrastructure. He has been the offshore installation lead and been involved with multiple subsea systems working with operators and drilling contractors to install equipment in accordance with procedures and safe working practices.

Expertise

Responsive team of problem-solvers

Our multi-disciplinary engineering and field service personnel have extensive experience in

complex offshore systems and integrity engineering. Because we are independent and know what to look for, we perform assessments quickly and often under extreme deadlines whilst providing unbiased mitigation solutions.

Root cause identification and remediation

We perform forensic engineering in the event of failure incidents to identify root causes, recommend design modifications and deliver remedial solutions. We offer turnkey design and delivery of integrity mitigation solutions using an agile and flexible supply chain cultivated over many years of integrity remediation projects to meet extreme project schedules.

Common issues

Degradation of the riser pipe, coatings or seals

Aircan and buoyancy can leaks and failures

Mechanical connection failures

Leaks due to excessive loading or corrosion

Excessive movement on seabed

Project Experience

Risers:

GoM oil spill emergency response: deepwater freestanding containment riser design, delivery and installation management.

GoM spar riser air can stem fatigue crack: engineering assessment, retrofit structural clamp design and delivery to mitigate issue.

West Africa water injection flexible riser failure: root cause engineering assessment, remaining life analysis, remediation assessment.

FPSO flexible riser i-tube fatigue: fitness for service assessment, material testing, inspection tool validation, structural clamp remedial solution design and delivery

GOM aircan pipework leak: engineering assessment, retrofit pipework design, delivery and installation

GoM evaluation of loss of VIV fairings or excessive fouling of VIV strakes on riser fatigue

GoM TTR reassessment of riser global strength and fatigue due to loss of centralization

GOM retrofit I-Tube: engineering assessment, retrofit I-tube design and delivery

North Sea drilling riser failure assessment

North Sea drilling riser choke and kill line stab pocket damage assessment

Wellhead housing pressure annulus relief (PAR): engineering assessment, retrofit PAR design and delivery.

GOM TTR splashzone joint leak: Independent third party (I3P) verification of pressure sealing clamp design, sealing qualification, fabrication and installation.

GOM SCR porch bushing installation tool detail design and analysis accomplished within 24 hours.

Subsea Components & Other Structures:

GoM subsea jumper oil leak: root cause engineering analysis, flowline buckling and walking analysis, subsea jumpers redesign.

NWS Australia downhole casing cross-over failure: loading assessment

GoM spar, TLP & semi post-hurricane strength re-assessments

GoM wellhead and conductor system snag loading strength assessment

NWS Australia subsea conductor system connector fatigue crack evaluation

GoM cathodic protection skid design

GoM wellhead mechanical connector unplanned disconnection assessment

North Sea dropped casing: damage evaluation of subsea flowlines

Secondary tree lockdown system

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Pete Padelopoulos

Senior Principal Engineer, USA

Pete Padelopoulos

Senior Principal Engineer, USA

Insights

Daniel Reagan

Principal Engineer

About

Daniel has over 17 years experience in deep water equipment design, manufacturing, testing, supply, offshore installation and inspection. As part of his early career roles and responsibilities he conducted global riser analysis, using finite element analysis (FEA) programs such as flexcom, to evaluate the strength and fatigue performance of riser system for major oil and gas operators. In addition to FEA work, spent several years designing, supplying and installing monitoring system for top tensioned riser (TTR’s), steel catenary risers (SCR’s), subsea jumpers and manifolds as well as tensioner systems.

The past 12 years have been spent overseen internal and external equipment design, manufacturing, quality, testing and delivery. Daniel has worked with and travelled to vendors throughout the world evaluating forging, machining and assembly facilities. As well as subsea equipment delivery management he have also been involved in a number of specialty subsea inspection campaign which included the development, testing and offshore inspection of critical subsea infrastructure. He has been the offshore installation lead and been involved with multiple subsea systems working with operators and drilling contractors to install equipment in accordance with procedures and safe working practices.