Monitoring Offshore Monopile Fatigue

EVENT: Wind Europe

1 Nov 2017

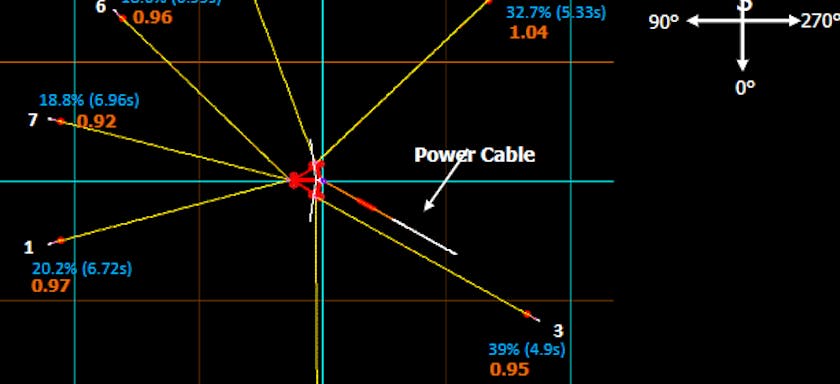

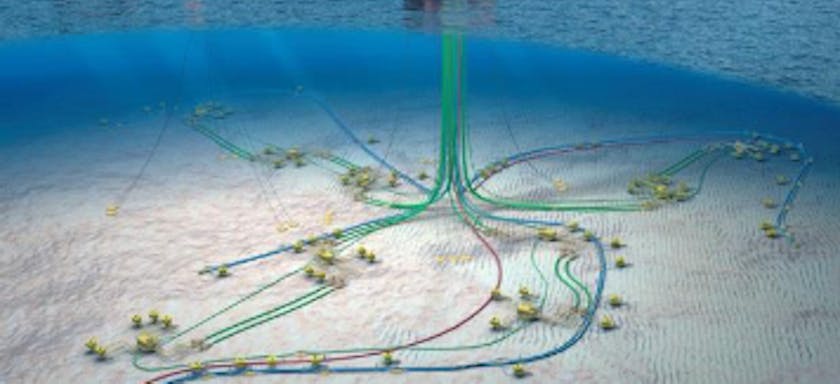

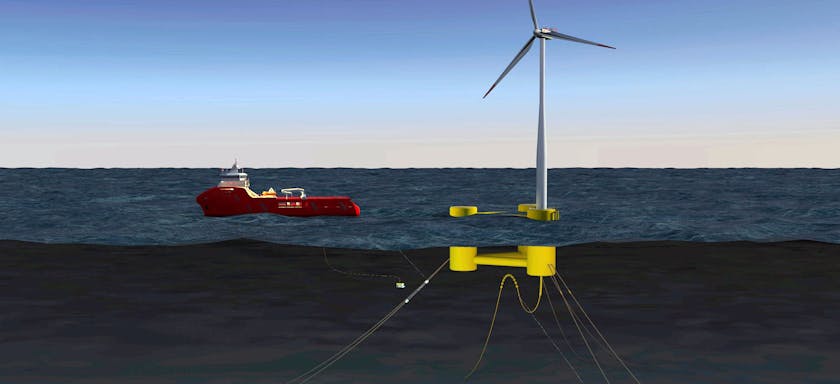

Fatigue loading on subsea monopiles used within wells has been an increasing problem in recent years for the oil and gas industry through the use of larger and heavier equipment on the monopole, longer operating durations and harsher environments. However, this is not a unique problem to the oil and gas industry as wind turbine monopiles also face large cyclic loading over extended life times. This challenge has prompted the widespread implementation of monitoring systems to confirm predictions of monopile loading and fatigue and ensure that: operations are conducted safely, inspection regimes may be properly specified; and life extension may be possible.

Monitoring system design requirements, data processing and evaluation of field measurements from a number of offshore monopiles are described. Monitoring systems for measurement of monopole fatigue require careful planning to ensure adequate quality of the data and cost effectiveness. The evaluation will determine the suitability of off-the-shelf equipment or the need for application specific devices. An example assessment of the requirements of measurement devices from which monopile fatigue can be derived is given that demonstrates the importance of integrated consideration of instruments, resolution and data processing methods in the selection and design of the system. Conservatisms in monopile design may be removed by using continued monitoring to increase understanding of these systems. Premature failures may be prevented through better understanding of the system loading and extension of the operating life of monopole foundations is shown to be possible.

Author

Alex Rimmer

Director, UK

About

Alex is a Chartered Engineer with a first-class master’s degree in mechanical engineering from the University of Bath and has been working for 2H Offshore since 2004. Alex has significant experience in the design and analysis of drilling and production systems for deepwater and shallow water developments, most notably as lead analysis engineer for BP’s Block 31 PSVM freestanding hybrid riser design project. Alex has taken on a number of managerial roles at 2H, including technical manager of the Norwich office, where he was responsible for integrating UWG’s shallow water riser and conductor engineering team and business into 2H. He has been a director in our London office since 2011.