Innovating Riser Configurations for Composite Pipe

New technology or materials rarely fulfil their true potential instantly. Digital cameras were first invented in 1975 but it wasn’t until the mid-90s that the first consumer products became available and the mid-00s before film was surpassed. The same is true in a lot of industries and oil and gas is just as guilty to be slow to innovate. This article will show innovations in riser design using composite pipe technology that’s been developed over the last decade.

21 Nov 2017

What Does Thermoplastic Composite Pipe Offer the Oil & Gas Industry?

Composite pipe is well known for being lightweight, which can be a blessing and a curse. It is highly resistant to corrosion and outperforms steel when it comes to fatigue performance. It has enormous potential to reduce CAPEX and OPEX and enables access to deeper reservoirs that would be too costly to extract energy from, or are entirely out of reach.

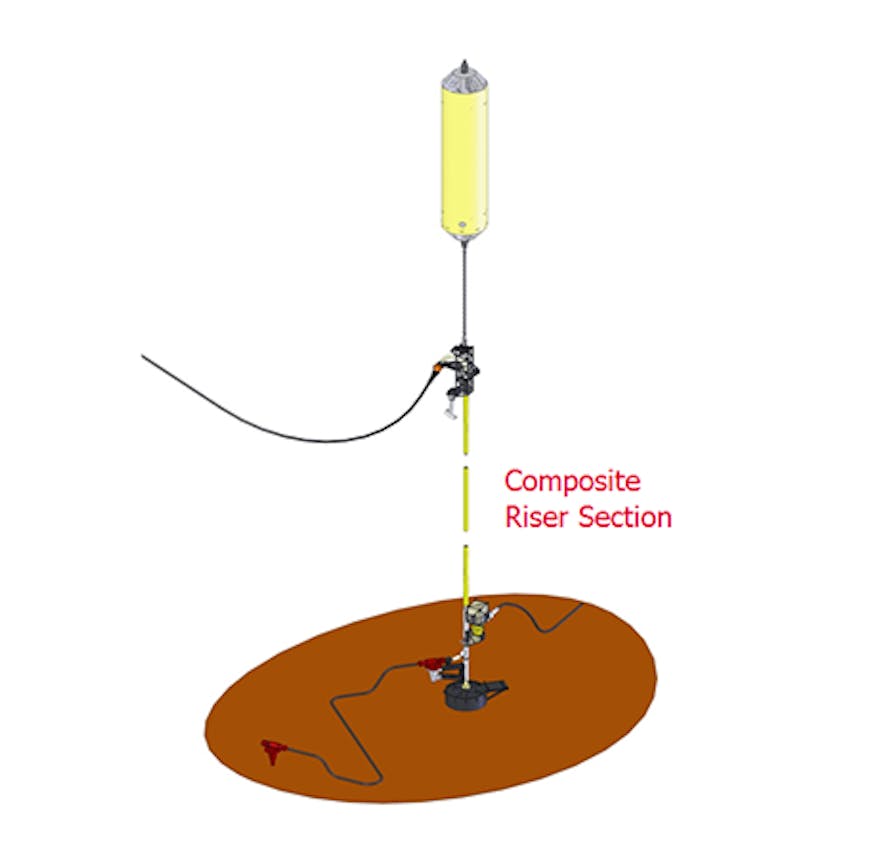

The Shoe Horn – Using Composite Pipe with Conventional Riser Configurations

When first assessing the potential for this technology, 2H took a conventional production riser design, a single line hybrid riser, and replaced the steel pipe section with the new composite pipe technology. The total system weight was reduced as the buoyancy tank, lower riser assembly and upper riser assembly were all able to be reduced in size due to the light riser section. This approach, however, had higher costs at 2,000 m water depth and didn’t become competitive until taken into much deeper waters, where the expenditure on heavy steel increases more rapidly than composites. Despite a lot of promise, applying the new technology to an existing design didn’t quite meet the needs of today’s industry.

A Clean Slate – An Organic Design Driven by the Material

A new technology actually deserves to stand on its own, so we went back to the drawing board and allowed the material properties of the pipe to drive the riser design in an organic design process.

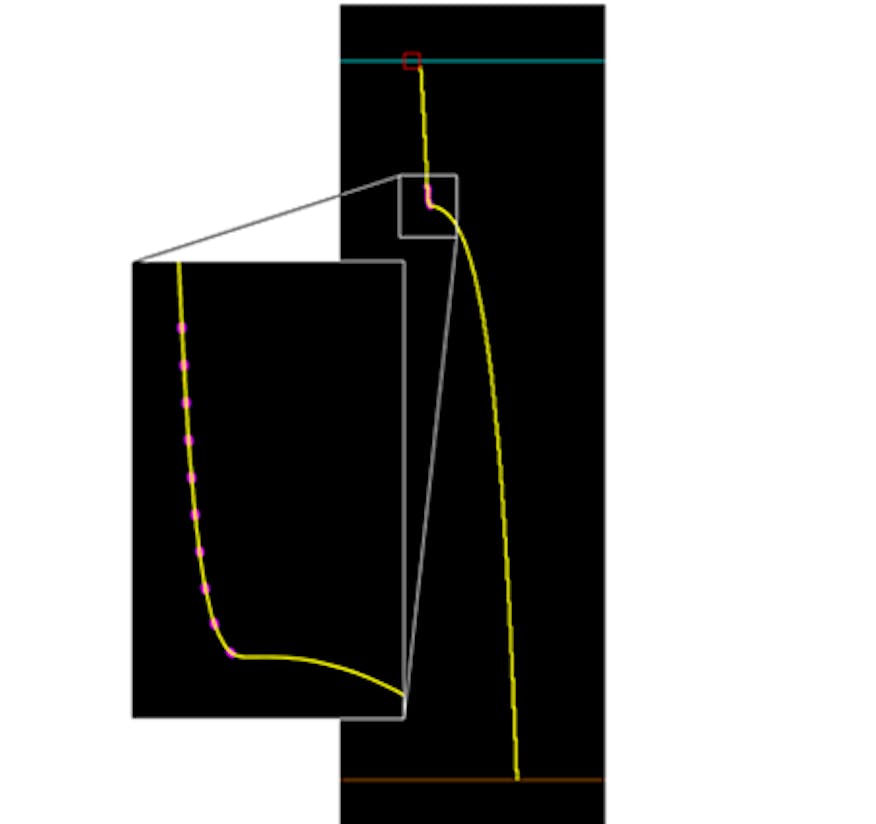

We started by assessing the minimum amount of pipe possible to use in a riser. Less pipe, less cost. The first configuration assessed was found to be acceptable with respect to extreme loading, however, during large vessel offsets, the tension along the riser increased significantly and we identified challenges for installation due to the buoyant nature of the composite riser pipe. What is most notable is that, due to the pipe buoyancy, the highest tensions were found at the seabed termination and not at the vessel.

The BOGOF – New Configuration Offers Value for Money

To reduce bending at the vessel hang-off and to decrease the tension variations, we added ballast close to the top of the riser and extended the pipe length. This decouples the vessel motions from the riser and adds flexibility to the whole system. By using ballast in this way, not only are the vessel loads significantly reduced, the seabed termination loads are reduced too. The small cost expenditure of additional pipe more than pays for itself with these reduced loads and their impact on vessel and foundation costs.

The Icing on the Cake – Innovative Approach Brings Additional Benefits

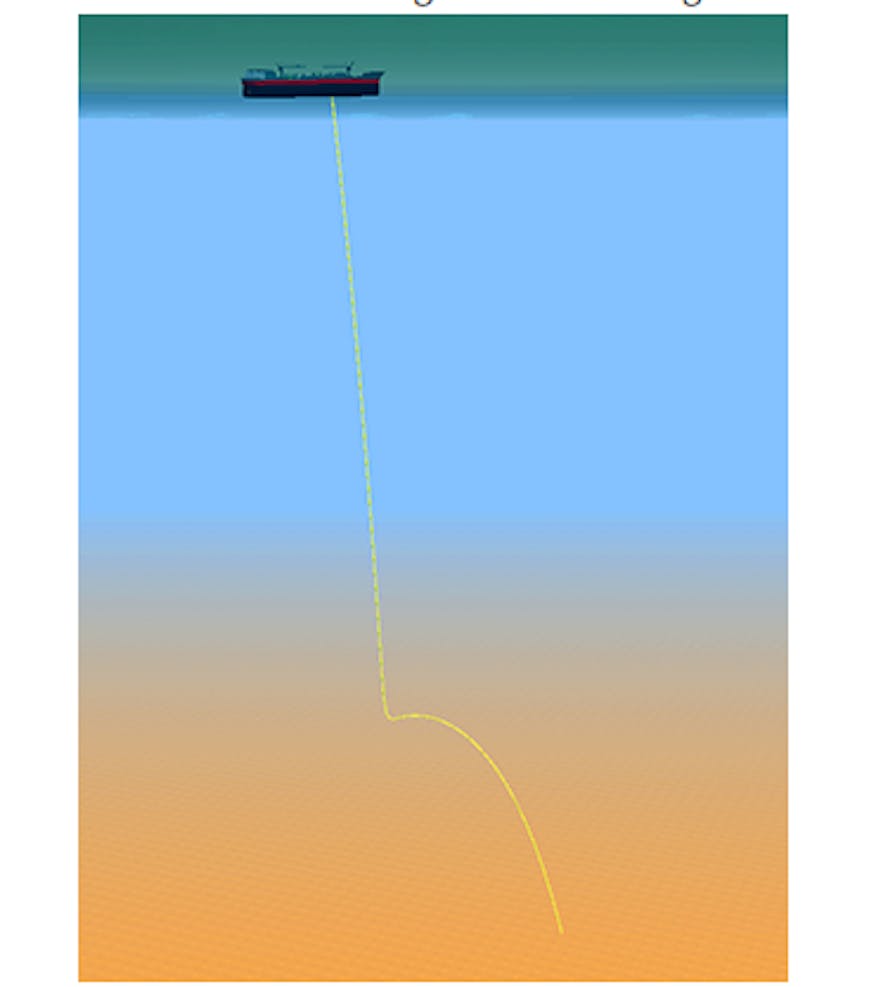

We placed the ballast close to the top of the riser as less ballast would be needed to combat the buoyancy of the pipe. We assessed heavier ballast and moved its location lower on the riser. The result was the same low vessel loads but now with significantly lower seabed termination loads too. This riser configuration now presents a simple solution with enormous flexibility and additional benefits. The riser, like the single line hybrid riser discussed earlier, could be pre-installed in order to take it off the critical path, further reducing costs and reducing project risk. Installation should also be quick and straightforward as only a small weight is required to weigh the lower section of the riser down, and could even be the riser foundation itself. We have called this configuration the weight-aided composite riser.

The Future for Composite Risers

A suitable application for a composite riser configuration like this would be marginal fields. Smaller vessels and lighter, redeployable risers would dramatically lower the cost of small pool field development and make these smaller reserves economically feasible.

Composites are currently beating digital cameras on the innovation front – around a decade from inception to the first consumer product rather than 15 years. Changing attitudes toward the technology may be a driver for this and it won’t be long before riser applications, in the form discussed or another, will begin cutting costs in the oil and gas industry.

If you’d like to know more about more about composite pipe applications, or our riser concept engineering experience, please get in touch.