CVA Requirements for Offshore Wind Developments in US Waters

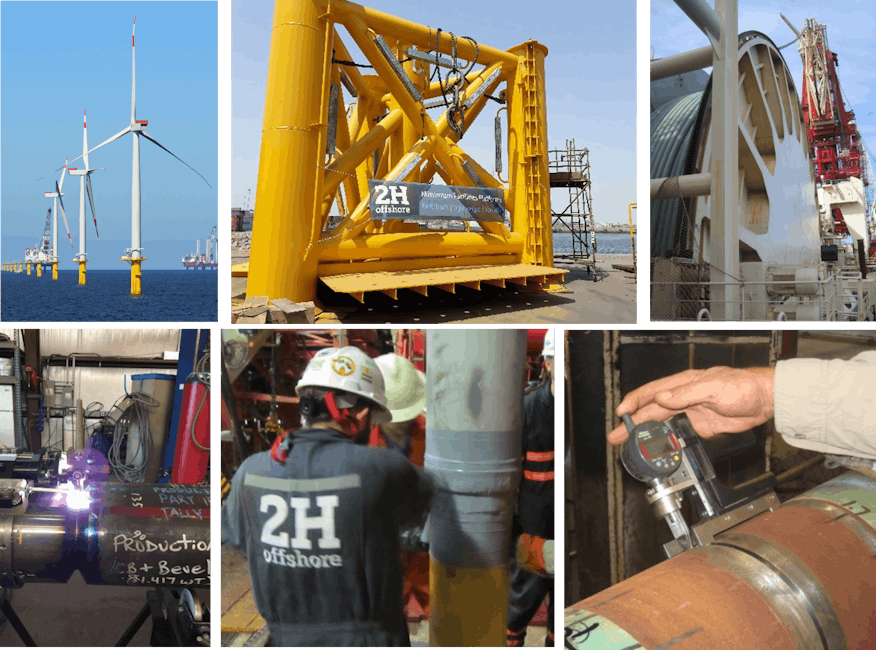

With few exceptions, all temporary and permanent fixed and floating offshore wind facilities in US waters are required to be verified by an independent certified verification agent (CVA). This article provides an overview of the CVA requirements in accordance with the Code of Federal Regulations 30 CFR 585. It includes lessons learned from 2H’s 20 years of experience conducting CVA and can be used as a high-level guideline for offshore wind developers.

28 Apr 2023

Author

Yusuf Arikan

Senior Principal Engineer - Renewables

About

Yusuf Arikan has over 15 years of structural engineering and project management experience in the design and analysis of various offshore structures including hydrodynamics of various floating offshore wind foundations. In recent years, he has been extensively involved in floating offshore wind projects, specifically the coupled assessment of the floater & turbine, and the design and analysis of mooring systems and power cables.

Yusuf holds a Bachelor’s degree from Bogazici University, Turkey and a Master’s degree from the University of Houston. He is a registered Professional Engineer (PE) in Texas and Project Management Professional (PMP).

Language

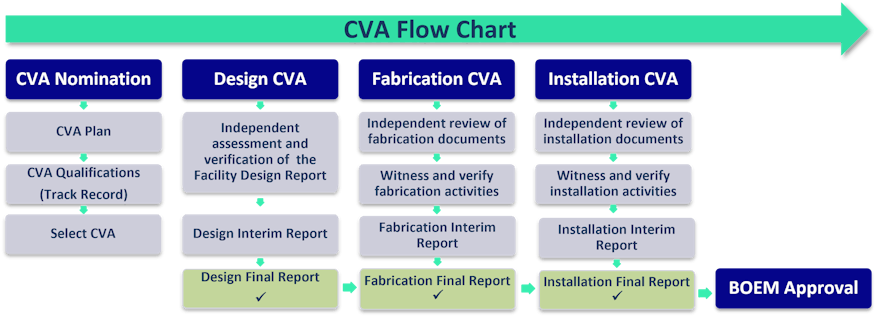

CVA Nomination

The first key point is that it is the responsibility of the developer to both nominate a CVA for BOEM approval and to fund the CVA process. The objectives, as outlined in 30 CFR 285, are to:

Ensure that facilities are designed, fabricated, and installed in conformance with accepted engineering practices

Ensure that repairs and major modifications are completed in conformance with accepted engineering practices

Provide BOEM with immediate reports of all incidents that affect the design, fabrication and installation of the project and its components.

The developer can nominate a different CVA for design, fabrication, and installation scopes, or a single CVA can be nominated for all scopes or any combination of the scopes. The CVA’s previous third-party verification experience including technical capabilities, organization size and type, in-house personnel availability, access to appropriate technology and a detailed work plan need to be included in the nomination package to BOEM for consideration.

CVA Responsibilities

After approval of the CVA nomination for the facility design scope, the CVA is responsible for independent assessment and verification of the following:

Planning criteria

Operational requirements

Environmental loading data

Load determinations

Stress analyses

Material designations

Soil and foundation conditions

Safety factors

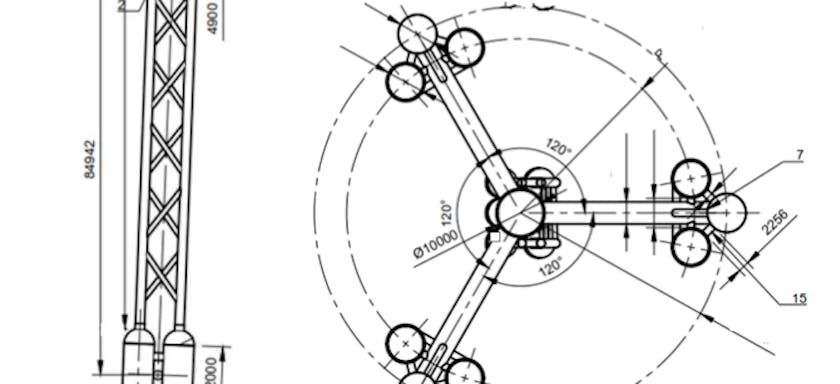

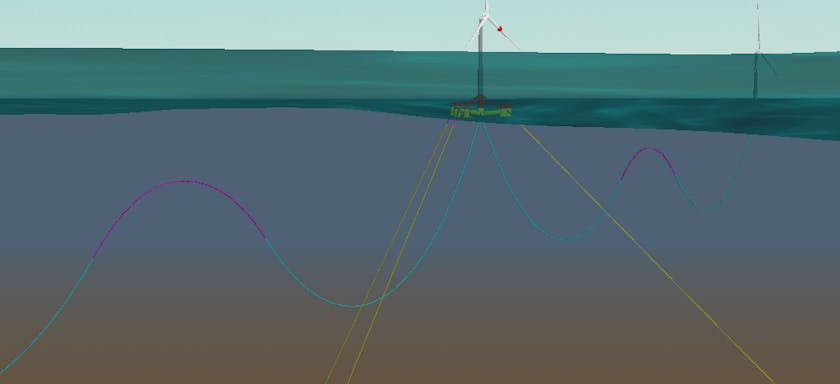

Structural integrity and stability of floaters for floating wind

Mooring and tethering systems for floating wind

Pilings, piling templates and anchoring systems

Typically, the design CVA is comprised of verification and acceptance of design inputs followed by review of all key design documentation.

The CVA is also required to make an independent review of fabrication and installation documents as well as regular fabrication and installation on-site inspections. During fabrication and installation inspections, the CVA is required to make periodic visits to verify all fabrication and installation activities are conducted in accordance with facility design, fabrication, and installation reports. During the fabrication inspections, the CVA is required to verify the following:

Builder’s quality control system

Material quality, identification and traceability

Fabrication procedures, welding procedure qualifications, and welding specifications

Destructive and non-destructive examination requirements, evaluation of results

Repair procedures

Corrosion protection systems and splash zone protection

Erection procedures

Dimensional checks of the overall structure including mooring lines and tensioning systems

During the installation of the facilities, CVA is required to verify:

Loadout and flotation procedures

Towing operation procedures to the specified location

Launching and up-righting activities

Submergence activities

Pile or anchor installations

Installation of mooring and tethering systems

Final component installation

Installation at the approved location

Upon completion of the activities outlined above, the CVA is required to submit both interim and final reports to BOEM for independent design verification, fabrication and installation inspection activities which include details of how, by whom, and when the CVA activities were conducted including the CVA activities carried out during the verification process, and summary of all key findings.

Characteristics of a Good CVA

The above provides a high-level overview of the CVA’s requirements. Lessons learned from previous projects we have conducted highlight the importance that the CVA understands its responsibility within the project. The CVA should focus on any major issues associated with fitness for intended purpose and safety, rather than minor preferential comments. It is the CVA’s responsibility to ensure that the facility design is per code, meets industry standards and is fit for purpose. Their objective is not to repeat the design work. Maintaining a good relationship with the company and the regulatory body is a key component of the role. Finally, having a strong, multi-disciplined team with pragmatic experience in both the design and verification side supported by industry-leading SME relationships helps to streamline the entire process. To date, this approach has resulted in a 100% approval rate for 2H as a CVA.

Our Track Record

As a global engineering company, 2H is frequently involved in the design, fabrication, and installation of fixed and floating offshore facilities and related components such as power cables, mooring and anchoring systems.

We have conducted design, fabrication and installation CVA activities for over 40 projects in US waters and several third-party independent verification scopes in various regions globally, some of which are listed below:

BP – Manuel SCR Design, Fabrication and Installation CVA

NNG Wind Farm – Casing Grouting Verification

Noble Energy – Big Bend-Dantzler SCR and Gas Lift Umbilical Design, Fabrication and Installation CVA

Tullow Oil – Jubilee Flexible Risers Procurement Management

Hess/Williams – Tubular Bells Design, Fabrication and Installation CVA

Hess/Enbridge – Stampede Design, Fabrication and Installation CVA

Noble Energy – Gunflint SCR Design, Fabrication and Installation CVA

Chevron – Jack St. Malo Production and Export SCR Design, Fabrication and Installation CVA

ATP – Mirage MinDoc TTR Design CVA

BP – Horn Mountain Spar TTR Design Verification

BP – Dorado and Galapagos Production SCR Design CVA

Chevron – Tahiti Development Production and Export SCRs CVA

ExxonMobil – Erha Production SCRs Design Verification

Statoil – Peregrino Weight Aided Wave (WAW) Risers Re-Analysis Study

ATP Oil & Gas – Gomez and Telemark Oil Flexible Catenary Riser Design, Fabrication and Installation CVA

Talow ERT – Phoenix Flexible Lazy Wave Risers Design, Fabrication and Installation CVA

Afren Okoro – Composite Flexible Riser As-Installed Verification

TRACS JIP – Tensioned Riser Assessment for Continued Service

Author

Yusuf Arikan

Senior Principal Engineer - Renewables

About

Yusuf Arikan has over 15 years of structural engineering and project management experience in the design and analysis of various offshore structures including hydrodynamics of various floating offshore wind foundations. In recent years, he has been extensively involved in floating offshore wind projects, specifically the coupled assessment of the floater & turbine, and the design and analysis of mooring systems and power cables.

Yusuf holds a Bachelor’s degree from Bogazici University, Turkey and a Master’s degree from the University of Houston. He is a registered Professional Engineer (PE) in Texas and Project Management Professional (PMP).

Language

To learn more about the CVA process, please get in touch!

Yusuf Arikan

Senior Principal Engineer - Renewables

About

Yusuf Arikan has over 15 years of structural engineering and project management experience in the design and analysis of various offshore structures including hydrodynamics of various floating offshore wind foundations. In recent years, he has been extensively involved in floating offshore wind projects, specifically the coupled assessment of the floater & turbine, and the design and analysis of mooring systems and power cables.

Yusuf holds a Bachelor’s degree from Bogazici University, Turkey and a Master’s degree from the University of Houston. He is a registered Professional Engineer (PE) in Texas and Project Management Professional (PMP).