Wellhead, Conductor and Casing Fatigue – Causes and Mitigation

EVENT: DOT

1 Nov 2012

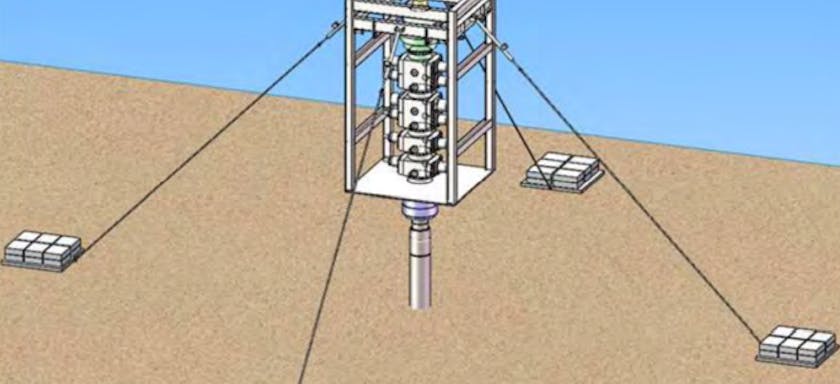

Drilling operations for subsea wells are typically carried out using drilling risers with subsea BOP stacks deployed from mobile drilling units. The drilling risers are subject to wave-induced motions both from vessel motions and direct wave loading, as well as vortex-induced vibration (VIV) due to current flow past the riser.

The motions are transferred down the riser to the wellhead, conductor and casing system and can cause fatigue issues at critical connectors and welds. The potential for severe fatigue loading of the wellhead system has increased over the last few years due to the use of 5th and 6th generation drilling vessels with larger BOP’s and considerably longer well operations, required to maximise output.

Equipment selection is often based on what has been used on previous wells and is not always application specific. Analyses done during the conceptual design stage often focuses on the drilling riser and the fatigue performance of the wellhead and conductor are often overlooked.

This paper describes the parameters that influence the riser motions transferred to the wellhead, conductor and casing system, and highlights those that are most damaging to fatigue performance. The options available to mitigate the fatigue issues through improved equipment configuration and specification are also discussed, together with various monitoring and fatigue tracking strategies to address these potential concerns.

Authors

Tze King Lim

Technical Manager

Tze King Lim

Technical Manager

Insights

Elizabeth Tellier

Director, Australia

About

Elizabeth is the director of 2H’s Perth office. She holds a bachelor’s degree in mechanical engineering and a minor in business from Texas A&M University. Liz has 20 years’ experience in the oil and gas industry with various types of riser design, subsea structural monitoring systems and subsea integrity management.

In 2010, Elizabeth relocated from Houston to Perth, Australia to launch a local office to support the growing subsea market in west Australia. She has since been an active member of the subsea engineering community in Perth with key involvement in the local SUT branch.

Major project involvement includes managing BP’s subsea & riser integrity programme, Anadarko’s Caesar Tonga freestanding riser pre-FEED and FEED, developing the Perth team’s drilling riser and conductor capability and delivering various subsea structural monitoring solutions to clients in Australia. Elizabeth has also been instrumental in the development of 2H’s renewable energy services to support floating and fixed offshore wind projects in the region.