Overcoming Installation Challenges to Wellhead and Conductor Fatigue

EVENT: OMAE

1 Jun 2013

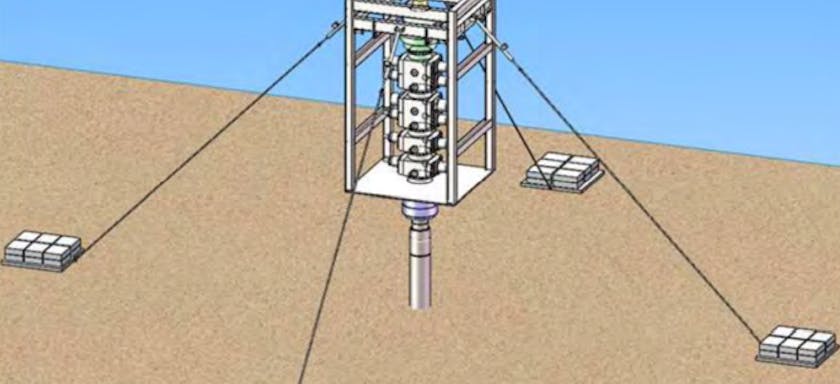

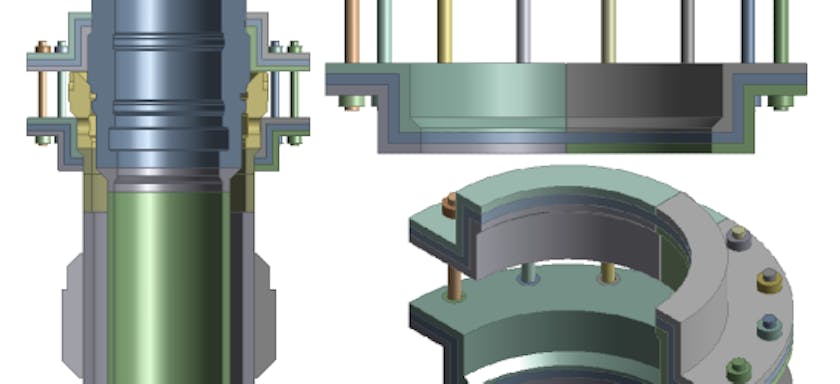

Subsea wells are typically drilled and completed using marine risers with subsea BOP stacks deployed from mobile drilling units. Wave and current induced riser motions are transferred to the wellhead, conductor and casing system which can then cause fatigue issues at the critical connectors and welds. In recent years, the risk of fatigue failure has increased due to the use of 5th and 6th generation rigs with larger BOP stacks, and longer well drilling and completion durations. During the design stage, the fatigue performance of the wellhead, conductor and surface casing is often overlooked.

During well construction, variations from design can occur in terms of wellhead stickup, wellhead lockdown and cement levels, both around the conductor and in the annulus between the conductor and surface casing. This paper describes analysis results showing the effect of these variations on the fatigue performance of the wellhead, conductor and surface casing. The recommended analysis load case matrix to account for these uncertainties is also presented, together with the need for as-installed assessments.

Recommendations on fatigue resistant designs with equipment configuration and specification options capable of meeting these challenges are presented. Wellhead monitoring and fatigue tracking strategies that can be implemented during drilling and workover operations to address these potential concerns and manage the risk are also discussed.

Authors

Elizabeth Tellier

Director, Australia

About

Elizabeth is the director of 2H’s Perth office. She holds a bachelor’s degree in mechanical engineering and a minor in business from Texas A&M University. Liz has 20 years’ experience in the oil and gas industry with various types of riser design, subsea structural monitoring systems and subsea integrity management.

In 2010, Elizabeth relocated from Houston to Perth, Australia to launch a local office to support the growing subsea market in west Australia. She has since been an active member of the subsea engineering community in Perth with key involvement in the local SUT branch.

Major project involvement includes managing BP’s subsea & riser integrity programme, Anadarko’s Caesar Tonga freestanding riser pre-FEED and FEED, developing the Perth team’s drilling riser and conductor capability and delivering various subsea structural monitoring solutions to clients in Australia. Elizabeth has also been instrumental in the development of 2H’s renewable energy services to support floating and fixed offshore wind projects in the region.

Insights

Ryan Koska

Principal Engineer

Ryan Koska

Principal Engineer

About

Ryan is a Principal Engineer in 2H’s Houston office. He holds a Bachelor’s degree in Ocean Engineering from Texas A&M University and has been working for 2H Offshore since 2007. Ryan has significant experience in the design and analysis of production risers as well as subsea rigid jumpers, along with operability and fatigue analysis of drilling riser, wellhead and conductor systems.

Insights

Tze King Lim

Technical Manager