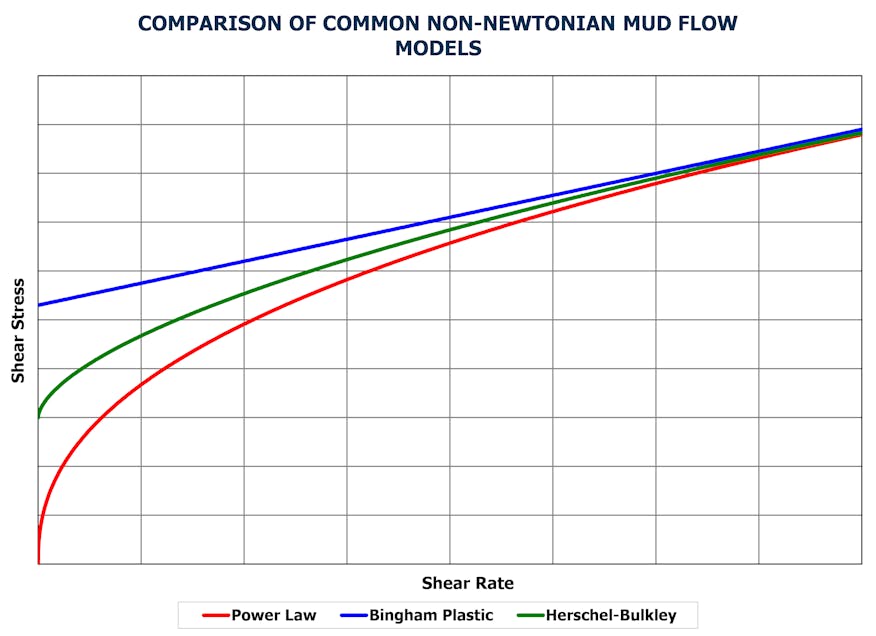

3 Mud Shedding Models Compared

To demonstrate the importance of choosing an accurate mud model, we evaluated the recoil response of an existing drilling riser system for the three mud models names above; Bingham Plastic, Power Law, and Herschel-Bulkley.

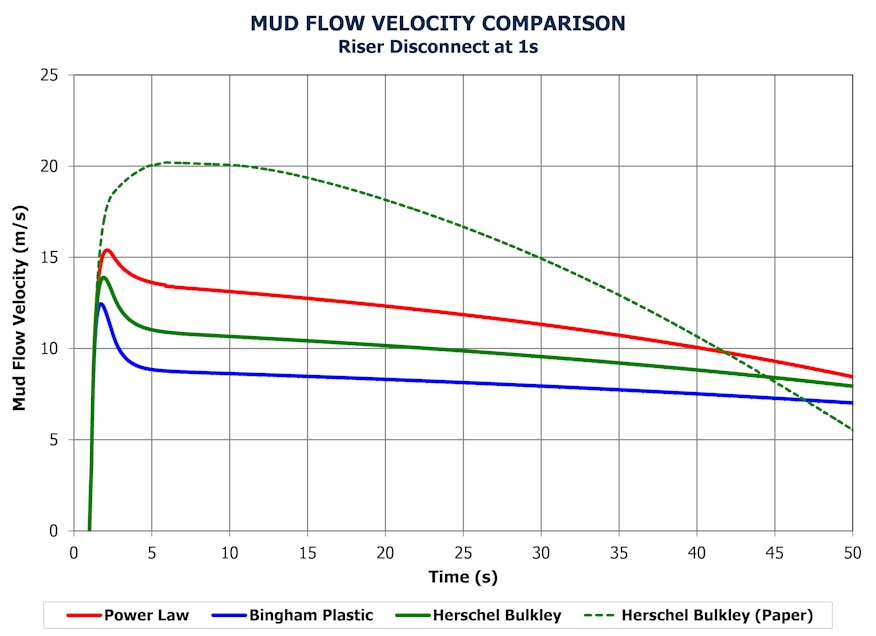

We used 2H’s proprietary software, 2HRECOIL, coupled with ANSYS. (2HRECOIL has been validated and benchmarked against commercially available tools). Mud flow was simulated to be consistent with the test results published in a Canadian Journal of Chemical Engineering paper “Laminar, Transitional and Turbulent Flow of Herschel-Bulkley Fluids in Concentric Annulus” by Founargiotakis et al (2008). The paper includes a mathematical framework for simulating mud flow using the Herschel-Bulkley model for a common concentric pipe configuration, as well as previous test results to help us benchmark our software.

Response of the anti-recoil system was captured in 2HRECOIL via detailed modelling of the tensioner hydro-pneumatic system, including adaptive closure of the anti-recoil valve during disconnect.

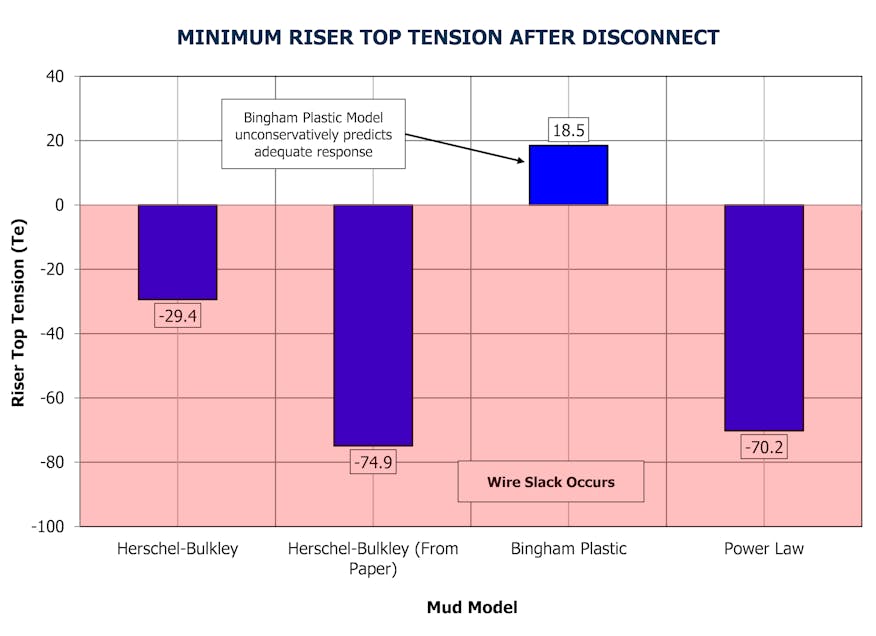

When the mud flow velocity and drilling riser top tension following disconnect were compared, we found noticeable differences depending on which mud flow model is considered. The Power Law model overestimates flow velocity compared to the Herschel-Bulkley model, while the Bingham Plastic model underestimates velocity. These differences in flow velocity result in different thrust forces applied to the base of the riser during recoil. This causes a difference in minimum riser tension immediately following disconnect.

Riser top tension is a key factor during recoil. In the test, using the Power Law and Herschel-Bulkley mud shedding models results in negative riser top tension and the recoil response is unacceptable. Negative tension can be detrimental, especially for wireline tensioner systems which experience slack in the wire ropes. This can lead to the wires jumping out of their sheaves as well as shock load damage to the wires as tension is quickly re-applied from the riser when it is in free fall. Using the Bingham Plastic model unconservatively results in tensions which remain positive and would be considered acceptable. Using the Herschel-Bulkley model identifies a potentially unsafe recoil situation that is not predicted by the more popular, but less accurate Bingham Plastic model.

Important to note:

Whilst benchmarking the mud flow simulation methodology described in Founargiotakis et al (2008), we discovered mistakes in several equations presented in the paper. Mud flow velocities for the Herschel-Bulkley model using the equations from the paper were significantly higher than those obtained from the corrected equations, as shown by the dashed green line in the figure below. Derivation of the ‘correct’ Herschel-Bulkley mud flow modelling equations to match the test results presented in the paper yields the solid green line also shown in Figure 2 below. Significant differences are evident in the mud flow velocity if the equations as presented in the paper are used.