Cost-Effective Transitioning of a Shallow-Water Exploration Well to Production

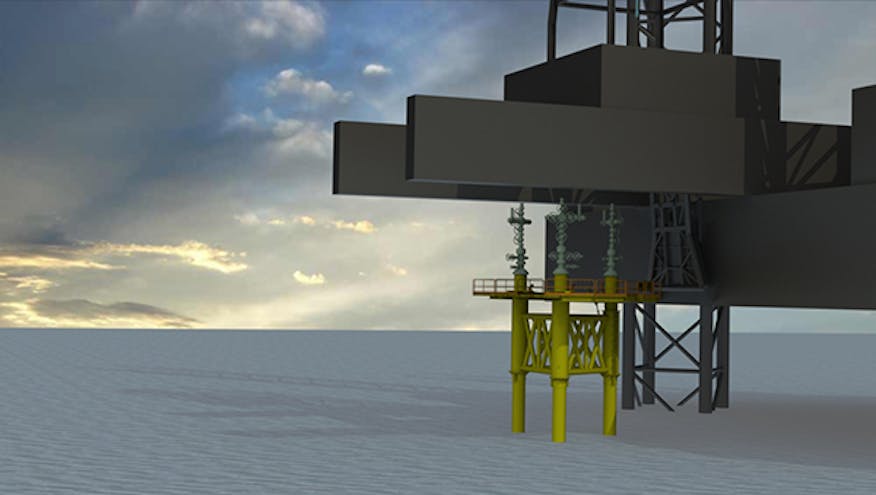

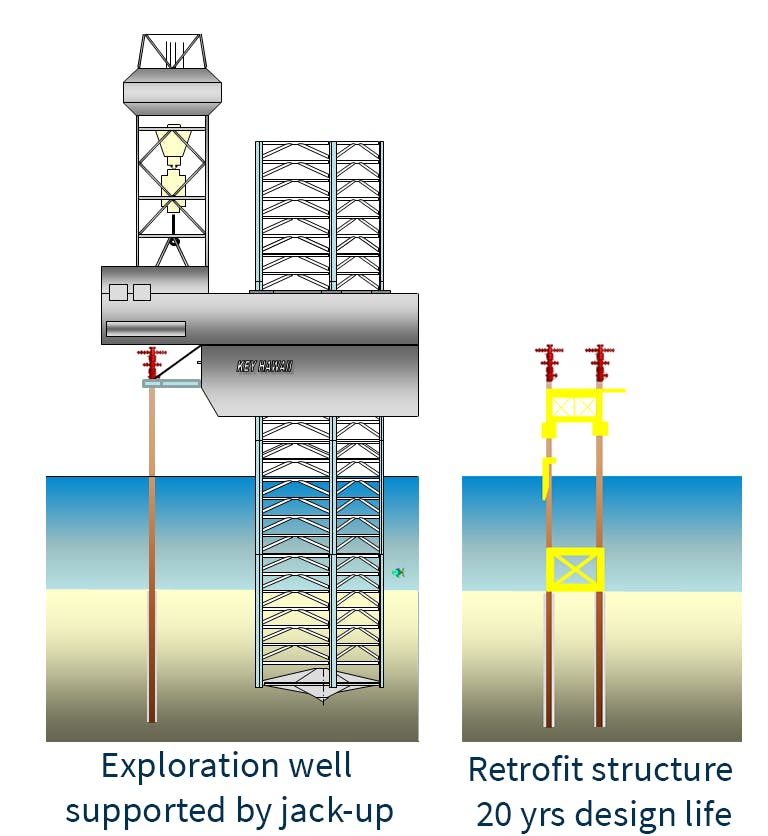

There are several ways to transition an exploration well into a standalone producer. Options include pre-installing a fixed platform, bringing in a MOPU (mobile offshore production unit) or using a low-cost retrofit conductor-supported platform (CSP).

19 Jun 2018

What is a retrofit CSP?

A retrofit CSP is a structure that is installed on the well after the drilling campaign. Structural and/or supporting components are installed around the free-standing conductor prior to departure of the jack-up rig. This arrangement provides strength, stability and fatigue resistance over the extended life of the well. Production fluid can be exported through an offloading hose. A topside deck from which wells can be controlled and maintained can be included if beneficial to the field development. Similarly, slots for optional future wells can be included through additional support conductors.

What should I consider when designing a retrofit CSP?

Be concise. Design creep is the kiss of death to this fast-track, light-weight structure. Consider the true functional requirements carefully and always revert to them when reviewing the design. Maintaining a minimum facilities mindset will ensure your structure does not become monstrous in size, weight, and of course, cost.

Be efficient. The design brief should minimise changes from existing platform designs and only include the use of readily available materials and local fabrication facilities, to minimize overall delivery time.

Be ready to go. The structures should be pre-fabricated and available on the quayside ready to transport before well-testing is complete so as not to interfere with rig drilling and testing operations or to unnecessarily delay rig departure.

Be flexible. Retrofit structures can be delivered within 6 months of project kick-off and are much smaller than their fixed platform counterparts making it entirely feasible to store them in a yard until needed (perhaps on the next well).